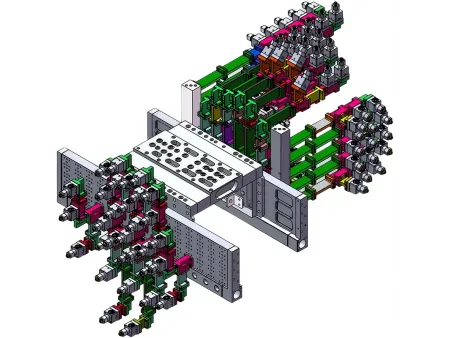

Die Spraying Tools (Contour Spraying)

Contour spraying for die casting molds uses robotic equipment to precisely and uniformly apply release agents and other media to designated areas of the mold surface, based on the three-dimensional shape, structural features, and preset paths of the mold cavity. Through “contour spraying,” the release agent only covers critical working surfaces such as mold cavities and runners, avoiding unnecessary spraying that causes waste or affects casting quality. It ensures uniform coating thickness to meet demolding requirements while preventing defects caused by excessive coating (such as bubbles and shrinkage porosity) or mold sticking caused by insufficient coating.

- Working Principle

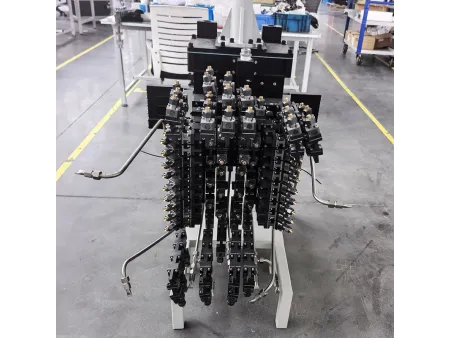

The clutch housing contour spraying fixture adopts a modular structure, designed according to cavity characteristics. It builds the spraying fixture and is equipped with an additional air-blowing function, enabling independent control of multiple spraying circuits and rapid drying of the mold cavity.

- Contour Design and Easy Installation

Multiple modular contour assembly methods ensure smooth delivery of liquid and air channels, allowing the spraying fixture to be adapted precisely to the mold.

- Multi-Angle and Adjustable Distance

With modular contour assemblies, spraying angles and distances can be flexibly adjusted.

- Low Maintenance Cost

The modular contour structure helps reduce maintenance costs during later use. Only damaged connectors need to be replaced for continued use.

- High Level of Design Professionalism

Professional 3D design of contour spraying fixtures enables spraying cycles of 25–30 seconds. With adjustments to the mold’s internal cooling structure, spraying cycles of under 20 seconds can be achieved.

- Micro spraying: Pure release agent with 100% active ingredients, water-based or oil-based, is precisely sprayed onto the mold surface using micro spraying equipment to form a lubricating isolation film.

- Low-volume spraying: High-concentration pure release agent (generally not less than 1:10) is precisely sprayed onto the mold surface using micro spraying equipment to form a lubricating isolation film.

- Mixed spraying: In one cycle, there can be a combination of two or three spraying methods among normal spraying, micro spraying, and low-volume spraying. Common combinations are normal/micro or normal/low-volume.

- Spraying fixture plate on the moving and fixed mold sides, length processed; surface with black anodizing.

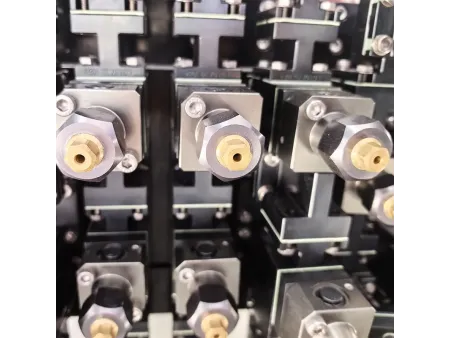

- Standard spraying mini valve.

- Internal mixing nozzle IM3.0.

- Additional air-blowing nozzle.

- Nozzle mounting accessories.

| Applicable release agents/die lubricants | Water-based, oil-based |

| Air pressure | 4-6bar |

| Release agent transfer pressure | 6-12bar |

| Spray method | Common spray |

| Spray circuits | 4 4 |

| Die spraying tool weight | Depending on actual application |

| Die spraying tool length | Depending on actual application |

- Working principle: The mobile EOC-type mixing station is mainly used for the mixing and pressurized delivery of die casting release agents. With an independent PLC control system and electronic flow meter for real-time flow monitoring, it achieves precise mixing of release agents for conventional spraying within a ratio range of 1:50 to 1:300. It can also monitor and measure the spraying consumption for each mold.

- Level display and alarm: Provides liquid level display (including mixed liquid and release agent stock solution) and level alarm functions.

- Multiple pressure adjustments: The mixed liquid is pressurized and delivered through a variable frequency pump. Within the 0–12 bar pressure range, adjustment can be made via the operation interface to ensure constant pressure and stable output.

- High accuracy: The quantitative accuracy of the mixed liquid ratio is controlled within ±3%, ensuring stable concentration of the mixed liquid.

- Flow recording: Monitors the consumption of release agent mixed liquid per mold, with usage alarm function. Automatically generates and stores historical flow records for up to 30 molds.

- Manual control: The mixing tank is equipped with a ball valve outlet switch interface, allowing manual control of all actuators and valves for quick cleaning of the mixing tank.