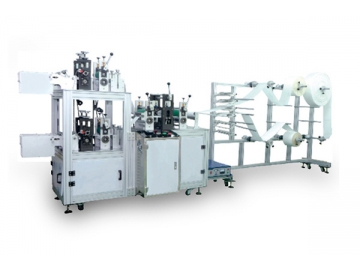

Ice Cream Cone Forming Machine

The ice cream cone forming machine employs the sucking nozzle to suck the printed paper from the paper bracket to the transportation chain. Subsequently, the paper is delivered to the forming mold and sprayed with thermosol simultaneously during paper conveying. The position, length and quantity of themosol can be adjusted during production. Efficiently, the glued paper will be dried and sent to the collector for automatic stacking and counting according to the preset stacking quantity.

Standard Configuration

1. Electric cabinet, touch screen and control system

2. Vacuum device and air compressor (air compressor is provided by customer)

3. Thermosol spraying device

4. Finished product stacker

5. Waste material collector

6. A set of forming dies

7. Five trimming knives

Features

1. The ice cream cone forming machine has high working efficiency with the productivity of 180pcs/minute.

2. Designed in compact structure, the ice cream cone making machine requires small space for installation.

3. With the load power of 5.5kW, the variable frequency speed regulation control system makes for high working accuracy.

4. The box structure drive system is distinguished by simple operation and convenient maintenance.

5. This range of paper cone forming machine is highly automatic, resulting in low labor cost and high productivity.

6. The ice cream cone forming machine is available in two models. The competitive price brings you favorable profits.

| Model | JXG-A(standard) | JXG-B(customized) |

| Output | Max. 180pcs/min | |

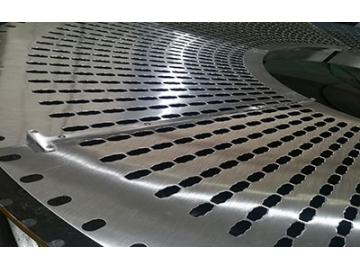

| Raw material | The ordinary paper or composite aluminum foil paper of 100g/m2, or dry wax paper exceeding 100g/m2. | |

| Optional component | 1. Spraying program controller 2. Air compressor | |

| Floor area | 2m×2m | |

| Min. height | 140mm | |

| Max. height | 220mm | 255mm |

| Ice cream cone conicity | 15-22° | According to customer requirements |

| Weight | 1000kg | |

| Packing size (L×W×H) | 1.25×1.15×1.9m, 1×0.6×0.85m | |