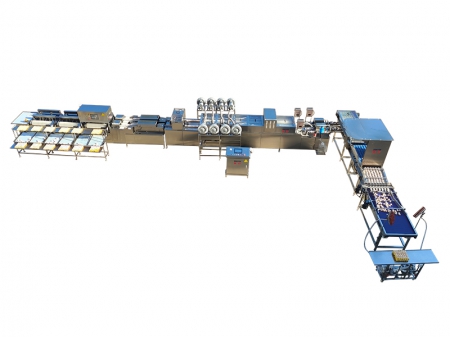

303AS Egg Processing Line with Washing & Grading (20,000 EGGS/HOUR)

The 303AS egg processing line integrates the 203A egg washer and the 106A egg grader, providing an advanced solution for high-volume egg processing. Built with a 304 stainless steel frame, it is highly corrosion-resistant and self-cleaning. With a capacity of 20,000 eggs per hour, this system includes an egg accumulator belt, LED candling, egg flow diverting, disinfection, washing, drying, orientation, electronic grading, counting, and egg collection conveyor for manual collection.

For enhanced automation, it can be equipped with the 602 vacuum egg lifter or directly connected to the centralized egg collection belt from the poultry house. Additional optional features include UV disinfection, inkjet printing, and AI visual inspection, forming a fully integrated egg processing solution.

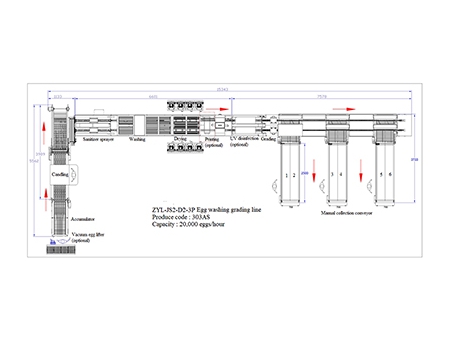

| Product name | Egg Processing Line |

| Product code | 303AS |

| Model | ZYL-JS2-D2-3P |

| Capacity | 20,000 eggs/hour |

| Material | Stainless steel |

| Power | 22.91kW |

| Voltage | 380V, 50Hz, 3-phase |

| Dimension (L*W*H) | 15.34*5.56 *2 M |

| Net weight | 2670KG |

| Gross weight | 4310KG |

| Function | Accumulating & candling & egg flow diverting, sanitizing, washing, drying, grading & counting, manual collection Optional vacuum egg lifter, UV disinfection, egg printer and visual AI detector |

- Manual Egg Loading/Vacuum Egg Lifter/Connect to the Rod Conveyor (Optional)

- Accumulating & Candling & Egg Flow Diverting

- Sanitizing

- Washing

- Drying

- Inkjet Printing (Optional)

- UV Disinfection (Optional)

- Visual AI Detection (Optional)

- Electronic Grading & Counting

- Manual Egg Collection

- Collection For Undergrad Eggs

It connects to the egg washer and consists of three parts: the egg loading system, a six-row LED candling device, and an egg flow diverting system. The LED candling lights installed beneath the six infeed rollers allow operators to visually inspect and manually remove defective eggs, such as cracked, misshapen, or dirty eggs. The egg flow diverting device then arranges the six-row eggs into two single rows, guiding them onto the rollers of the dual-lane egg washer.

Manual Egg Loading

Eggs could be manually placed onto the accumulator as well.

Vacuum egg lifter uses a 5x6 suction cup head to lift 30 eggs per cycle from egg trays using negative pressure.

Connect to the Rod Conveyor

The system directly connects to the central egg collection belt from the poultry house, allowing eggs to flow automatically into the accumulator belt. This belt is divided into two sections: an egg storage area and a sorting area. If the accumulator belt reaches full capacity, the sensors will automatically adjust speed to ensure efficient egg filling while preventing damage.

It includes a proportional dosing system, featuring a filter, doser, and liquid tank. Operators can add cleaning agents or disinfectants (provided by the customer), and the doser automatically mixes and sprays the solution onto the eggs at a 1:100 ratio (factory setting).

The dual-lane egg washer is designed for minimal water consumption, using only 300 liters per hour (150 liters per channel). The brush system is designed for optimal egg surface cleaning, with adjustable brush speed based on egg cleanliness levels to minimize shell damage. This achieves the perfect balance of minimum water usage, maximum cleanliness, and high egg quality.

Features an advanced air-drying system, combining air-drying brushes and nozzles to ensure rapid drying without overheating the eggs. Drying efficiency reaches up to 98%, depending on ambient humidity.

The egg printer can be installed at the end of the dual-lane egg washer or before the dual-lane egg grader. As eggs pass under the photoelectric sensor, the printer is triggered, enabling the printing of text, numbers, images, logos, Julian dates, and expiration dates on the eggs.

An optional UV disinfection module can be installed to sanitize eggshells using ultraviolet light, ensuring compliance with higher food safety standards.

The AI visual inspection system operates with a non-contact design, using high-definition cameras mounted at the top of the inspection cabinet to capture images of eggs rotating on the infeed rollers. Using near-infrared (NIR) light, advanced image processing, and AI algorithms, the system automatically detects large crack, hair line crack, dirty, or defects. Defective eggs are immediately removed from the processing line to ensure only high-quality eggs continue.

This system integrates two single-row electronic graders, processing up to 20,000 eggs per hour. The 303AS Egg Processing line can sort eggs into 3–6 weight grades with an accuracy of ±1g.

A color touchscreen allows users to adjust weight grading settings easily. The built-in smart self-diagnostic system displays error messages on-screen, helping users quickly identify and resolve issues. Additionally, the system is equipped with Wi-Fi connectivity, allowing remote monitoring and troubleshooting via the internet.

The standard configuration includes three egg collection conveyors for manual egg collection. If needed, each collection conveyor can be divided into two sections, allowing operators to sort eggs by two weight categories. Graded eggs are manually packed into egg cartons (with lids) and egg trays (without lids).

Eggs that do not meet grading requirements are directed to the undergrade egg collection table at the end of the machine.