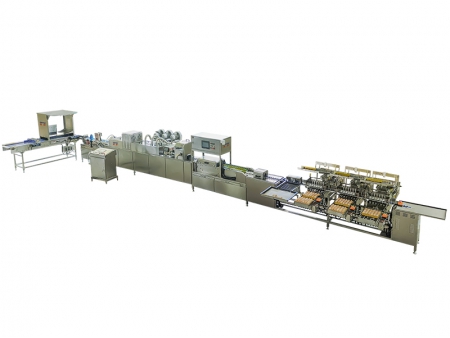

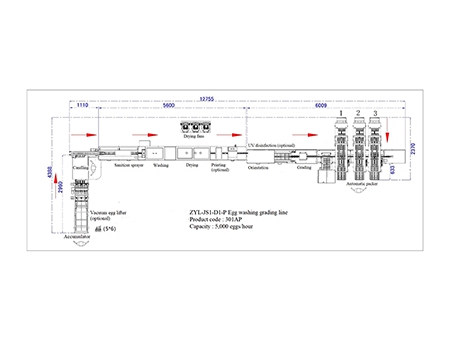

301AP Egg Processing Line with Washing & Grading (5,000 EGGS/HOUR)

The 301AP egg processing line is composed of the 201A egg washer and the 102BP egg grader, offering a highly efficient solution for egg processing. Built with a corrosion-resistant, self-cleaning 304 stainless steel frame, the 301AP system has a processing capacity of 5,000 eggs per hour. It integrates an egg accumulation belt, LED candling, disinfection, cleaning, drying, egg turning, grading, counting, automatic packaging and manual egg collection. For easier egg loading, you can opt for the 602 vacuum egg lifter or directly connect to the central egg collection belt from the poultry house. Optional features include UV disinfection, inkjet printing, and AI visual inspection to enhance functionality.

| Product name | Egg Processing Line |

| Product code | 301AP |

| Model | ZYL-JS1-D1-P |

| Capacity | 5,000 eggs/hour |

| Material | Stainless steel |

| Power * | 11.631kW |

| Voltage * | 220V, 50Hz, single phase or 380V, 50Hz, 3-phase |

| Dimension (L*W*H) | 12.76*4.4*2 M |

| Net weight * | 1550 KG |

| Gross weight * | 2220 KG |

| Function | Accumulating & candling, sanitizing, washing, drying, orientation, grading & counting, auto packing and manual collection table. Optional vacuum egg lifter, UV disinfection, egg printer and visual AI detector |

- Manual Egg Loading/Vacuum Egg Lifter/Connect to the Rod Conveyor (Optional)

- Accumulating & Candling

- Sanitizing

- Washing

- Drying

- Inkjet Printing (Optional)

- Orientation & UV Disinfection (Optional)

- Visual AI Detecting (Optional)

- Electronic Grading & Counting

- Automatic Packing

- Manual Egg Collection

- Collection For Undergrade Eggs

The 301AP egg processing line connects seamlessly with the egg washer. It consists of three parts: the egg loading system, a candling device with 3 rows of LED lights, and a single-row sorting device. The LED lights beneath the rollers illuminate the eggs, allowing manual identification of broken, deformed, dirty, or defective eggs. The eggs are then sorted into a single row before entering the washing system.

Manual Egg LoadingEggs can be manually placed onto the 605AS egg accumulator as well.

The vacuum egg lifter uses a 5x6 suction cup head to lift eggs from the trays using negative pressure. It can lift up to 30 eggs at a time.

Connect to the Rod Conveyor

The system connects directly to the central egg collection belt from the poultry house. Eggs flow automatically into the accumulator belt, which is divided into two sections: the egg storage area and the sorting area. If the accumulator belt becomes too full, the sensors automatically slow the process to ensure optimal egg placement on the rollers, preventing eggs from being damaged.

It is equipped with a proportional dosing system, including a filter, doser, and liquid tank. Operators can add cleaning agents or disinfectants (provided by the customer) into the tank. The doser automatically mixes and sprays the solution onto the eggs at a 1:100 ratio (factory setting), ensuring proper sanitation.

Designed for minimal water consumption, using only 150 liters per hour. The specially designed brush system ensures that all parts of the egg’s surface are thoroughly cleaned. The brush rotation speed can be adjusted according to the level of dirt on the eggs, reducing shell damage while maintaining optimal cleaning efficiency and egg quality.

Features an air-drying system, which combines air-drying brushes and nozzles to ensure eggs dry quickly after washing. This system effectively dries eggs without excessive heat exposure, maintaining egg quality. Drying efficiency can reach up to 98%, depending on ambient humidity.

The 401H egg printer can be installed at the end of the washer or before the grader. When eggs pass under the photoelectric sensor, the printer is triggered. It can print text, numbers, images, logos, Julian dates, and expiration dates on the eggs.

Specially designed to automatically adjust the eggs so that the larger end (air cell) faces upward, ensuring longer shelf life after packaging. An optional UV disinfection module can be installed to sanitize the eggshells using ultraviolet light, enhancing food safety standards.

The AI visual inspection system uses a non-contact design, eliminating the need for operators or equipment to physically touch the eggs. High-definition cameras are installed at the top of the inspection cabinet, capturing images of eggs rotating on the infeed rollers. Using near-infrared (NIR) light, advanced image processing, and AI algorithms, the system automatically detects large crack, hair line crack, dirty, or other defects. Defective eggs are automatically identified and removed from the processing line, ensuring only high-quality eggs continue.

The 301AP egg processing line has a processing capacity of 5,000 eggs per hour and sorts eggs into 4–5 weight grades with an accuracy of ±1g. The system includes a counting function, recording the number of eggs per grade, daily production, and total processed eggs.

A color touchscreen allows users to adjust weight settings and parameters directly. The self-diagnostic function displays errors on the screen, enabling quick issue resolution. Additionally, Wi-Fi connectivity allows for remote monitoring and troubleshooting via the internet, ensuring quick software issue resolution.

The 301AP egg processing line includes three automatic tray packers and one manual collection table. Graded eggs are automatically packed into the correct lanes based on weight, filling egg cartons (with lids) and egg trays (without lids) accordingly.

Eggs that are not automatically packed are transferred to the manual collection lane, which can be divided into two sections to accommodate two weight categories as needed.

Eggs that do not meet the grading standards are transferred to the undergrade egg collection table at the end of the machine.