Transformer Based Plasma Cutter

- LGK-40

- LGK-63

- LGK-100

1. The LGK series transformer based plasma cutter adopts compressed air to save the cost of expensive gas. It runs safely and reliably.

2. Additionally, this series of cutter offers rated duty cycle of up to 100%. It can continuously work under normal operating conditions.

3. As a metal cutting machine, this product is able to cut almost all kinds of metal sheets and metal tubes such as the ordinary steel, stainless steel, drilling steel, metal alloy, and the cast iron, etc.

4. As a kind of machining equipment, our product is ideal for use in different industries including the vehicles, shipbuilding, chemicals, boilers, food, pharmaceuticals, kitchens, environment, and more.

Characteristics

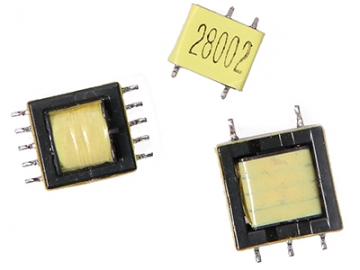

1. The LGK series transformer based plasma cutter adopts a specially designed high-leakage transformer to provide plasma cutting arc. It can realize high-speed, high-precision cutting, narrow kerf improvement, and no deformation.

2. The integrated structure of our product is horizontally installed. Wheel and lug allows the cutting equipment to be moved or hoisted more conveniently.

3. This series of transformer based plasma cutter is designed with thermal protection function. When the interior temperature of the machine exceeds a preset temperature, an overheat indicator will be turned on to give an alarm.

4. As cutting gas source, compressed air is economical and practical. It does not cause any environmental pollution. If used to cut 12mm thick carbon steel plates, our product can work 4 times as fast as a flame cutting machine. Its operating cost is only one third of that of a flame cutter.

5. A high-frequency arc starter features fast speed and high reliability. It can cut different workpieces that have unclean surfaces or paint coatings, etc.

6. The surface of our machine has gone through multiple working procedures such as the acid pickling, parkerizing, electrostatic spray, and more. Therefore, its film coating is smooth, firm, corrosion-resistant, and non-shedding.

Technical Parameters

| Type | |||

| Power Voltage/Frequency | 380V/50Hz | ||

| Phase Number | 3 | ||

| Rated Input Capacity | 9.5KVA | 15.8KVA | 28.3KVA |

| No Load Voltage | 220V | 245V | 205/270V |

| Rated Duty Cycle | 60% | ||

| Cutting Thickness | 1~13mm | 1~18mm | 2~30mm |

| Rated Load Voltage | 40A | 63A | 100A |

| Gas Flow | 110L/min | 130L/min | |

| Rated Load Voltage | 96V | 105V | 120V |

| Torch Cable Length | 5M | ||

| Compressed Air Pressure | 0.4MPa | 0.5MPa | |

| Weight | 72kg | 84kg | 112kg |

| Dimensions | 655×395×740(mm) | 705×445×775(mm) | |