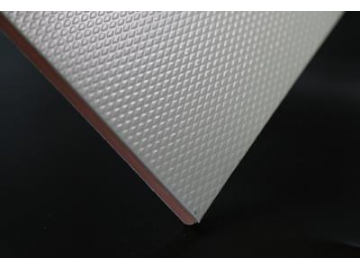

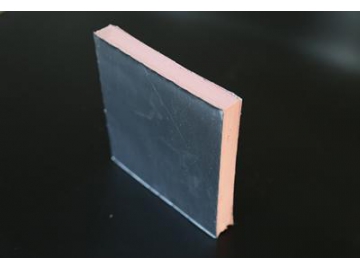

XPS Underfloor Heating Insulation Board

Description

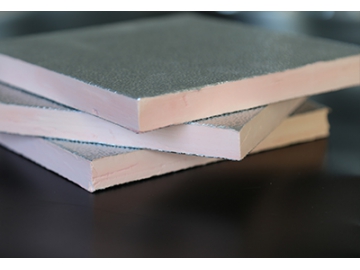

The XPS underfloor heating insulation board is an extruded closed cell foamed rigid foamed board formed through a process that includes injecting a catalyst while heating and mixing a polystyrene resin and polymer. The XPS features a perfect closed-cell honeycomb structure, allowing it to have an extremely low water absorption (almost no water absorption), low thermal conductivity, high pressure resistance, and an excellent aging resistance (approximately no aging degradation during normal usage).

Application

The XPS underfloor heating insulation board is widely used for heat preservation in roofing, steel roofs, colored steel tile, walls, cold storage, refrigerated cars/trucks, compound flue pipes, floor material, cleaning shops, building basements and outdoor social gathering areas. It is a heat insulation and non-hygroscopic that is inexpensive without sacrificing quality or performance.

Characteristics of XPS underfloor heating insulation board

1. Good heat insulation and preservation:

The XPS board features a high thermal resistance, low linearity and a low expansion ratio. Its structural rate of a closed hole is more than 90%, which assists in forming a vacuum layer to avoid air flowing and radiation in order to ensure durability and stability of the thermal insulation performance. Its leading advantage is self-evident when compared to foamed polyurethane with a closed hole rate of 80%. It has been proven that 20mm thick XPS insulation board insulation effects are equivalent to that of a 50mm thick foamed polystyrene, and a 120mm thick concrete perlite, making this material an ideal solution for building insulation materials.

2. Excellent high strength compression resistance:

The XPS board has an extremely high compressive strength and impact resistance due to its specialized structure. According to the different models and thicknesses of the XPS board, its compressive strength reaches between 150 and 500KPa with the ability to withstand the ground load of each system. This has made it ideal for use in heat preservation in geothermal engineering, expressways, runways, outdoor social gathering areas, large cold storage and vehicle interior decoration.

3. High quality hydrophobic property and moisture resistance:

Water absorption is an important parameter for measuring insulation materials. The thermal insulation property of any thermal insulation material drops after water absorption. In a low temperature environment, any water absorbed will easily freeze, which destroys the structure of thermal insulation material, thus reducing the compressive and thermal insulation properties of the board. In the XPS board, because the polystyrene molecular structure itself does not absorb water, the molecular structure will remain stable. There are also no gaps, which solves problems caused by leakage, penetration, frost formation and condensation of other materials.

4. Lightweight and easy to use:

The fully closed cell foaming chemical structure of the XPS board and its honeycomb physical structure make it both lightweight and strong, easy to cut and transport, and it is not easy to break. This board is also easy to install.

5. Excellent stability and corrosion resistance:

During long term usage, the XPS board does not age, decompose or produce harmful substances. Its chemical properties are extremely stable and will not degrade due to water absorption or corrosion, while still maintaining an excellent performance even under high temperature conditions. Even though the service life is 30 to 40 years, it will retain its performance for the entire period with no degradation, mildew or harmful substance production.

6. Good environmental performance:

The XPS board has been tested by relevant country government agencies, and its chemical properties have been found to be stable, non-volatile and harmless. Production is carried out sing environmentally friendly raw materials, and does not produce any industrial pollution, making the product an environmentally friendly building material.

WT Thermal Insulation Material is manufacturing and offering aluminized fabrics and fiberglass coated products and some others feature aluminum foils or silicone laminating, these products extend to aluminum foil wrap, aluminum foil laminated fabrics, and adhesive aluminum tapes, aluminum foil fabrics covered insulation foam board etc. We can offer different products that are made with aluminum foils by coating, laminating, or covering; rich experiences and enough knowledge of manufacturing aluminum foil based products is our confidence to provide quality products to global markets.

Index

thermal insulation board, rigid foam board, extruded polystyrene board