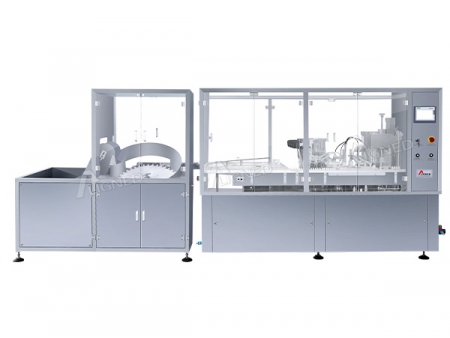

Aseptic Filling and Closing Machine (for Eye-drop)

ALY Series

This aseptic filling and closing machine is designed specifically for 2-10ml eye drop filling and capping. It incorporates advanced sterile technologies, supports CIP cleaning, and meets strict hygiene standards, making it an ideal choice for any business requiring a reliable and hygienic solution for their eye drop filling and capping needs. It is equipped with robotic arms and vacuum technology, which ensures superior precision and stability. It can be easily integrated with bottle unscrambling, ionized air purification, and other systems, allowing the formation of a fully automated production line that can seamlessly handle processes such as bottle sorting, rejection, filling, stoppering, capping, and sealing.

| Model | | |

| Filling Capacity Options | 2-10ml | 2-15ml |

| Filling Nozzles | 2 heads | 4 heads |

| Plugging Head | 1 head | 2 heads |

| Capping Head | 1 head | 2 heads |

| Filling Speed | 40-50bpm (depending on the filling volume) | 80-100bpm (depending on the filling volume) |

| Filling Accuracy | ±1% | ±1% |

| Supply Voltage | 380V/220V 50Hz | 380V/220V 50Hz |

| Power | 3.0kW | 3.0kW |

| Weight | Approxi. 1000kg | Approxi. 1000kg |

| Dimension | 2600×1150×1700mm | 2600×1150×1700mm |

- The filling process is carried out using a high-precision servo-driven peristaltic pump, which provides accuracy and reliability. Both the pump and needle can be disassembled without the need for additional tools. The needle has been crafted from 316L stainless steel, offering durability and enhanced hygiene standards.

- The stoppering and capping section features robotic arms for precise placement, offering high accuracy with "no bottle, no stopper/cap" automation. Each workstation is controlled independently by protected optical fiber sensors, and robotic arm adjustments can be made without tools.

- The advanced capping mechanism includes a third-generation capping head with an automatic slip feature. A bottle-gripping system prevents bottle rotation during capping, avoiding any damage to the caps.

- The system is controlled by an intelligent PLC system that supports both standalone and integrated operation. The control system monitors the status of each workstation and displays this information on the touchscreen. In the event of a fault, the system automatically stops the machine, thus ensuring safe and reliable performance.

The working principle is as follows: bottles are fed into the filling section via a sorting disc. A four-head servo peristaltic pump is used to fill the bottles as they rotate on the turntable. Once the bottles have been filled, they proceed to the stoppering and capping section, where the stoppers and caps are delivered through electromagnetic vibration. The final stage is the capping process, during which the caps are securely fastened.