Horizontal Ribbon Mixer

Industrial mixing machine for gentle blending of ingredients

S&L horizontal ribbon mixer is ideal for gentle blending of ingredients, consisting of a U-shaped vessel, ribbon agitator, and drive unit. The ribbon-shaped blades are usually made into double layers. During operation, the outer ribbon conveys material towards the discharge, while the inner ribbon transports material away from the discharge, forming convective mixing. The agitator is the most important component of the mixer, and is also optional in paddle blades, and choppers can be added to adapt to different materials.

The vessel lip can be made into an arched or fully open design. The arched design can withstand pressure, while the fully open design facilitates the cleaning of the equipment's interior. The advantages of this industrial mixing machine are its wide applicability, high mixing uniformity, short mixing time, and high loading coefficient.

- Chemical industry: dyes mixing

- Cosmetic: cosmetics powder mixing

- Agricultural: animal feed granules and powders mixing

S&L horizontal ribbon mixer is suitable for mixing and blending powders and powders, particles and powders, as well as powders and small amounts of liquid additives.

Pressure/vacuum inside mixer, Jacket for cooling or heating

- Ribbon and Paddle agitator design are available

- Gentle mixing for fragile materials

- Easy cleaning and maintenance

- Food-grade packing gland seal

- GMP design with FDA certificate of non-metal part of mixer

- Drying/cooling jacket and vacuum design is optional

- Heavy duty design

- Batch or continuous mixing process

| Gross Volume (L) | Effective Volume (L) | Overall Dimensions (mm) | Shaft Speed (rpm) | Approx. Weight (kg) | ||

| A (length) | B (width) | C (height) | ||||

| 100 | 40-60 | 1300 | 550 | 1100 | 101 | 310 |

| 300 | 120-180 | 1900 | 700 | 1200 | 56 | 570 |

| 500 | 200-300 | 2200 | 850 | 1400 | 52 | 840 |

| 1000 | 400-600 | 3200 | 1070 | 1600 | 43 | 1760 |

| 1500 | 600-900 | 3400 | 1170 | 1700 | 38 | 1940 |

| 2000 | 800-1200 | 3750 | 1270 | 1900 | 35 | 2740 |

| 3000 | 1200-1800 | 4100 | 1460 | 2100 | 30 | 3340 |

| 4000 | 1600-2400 | 4400 | 1570 | 2250 | 27 | 4210 |

| 5000 | 2000-3000 | 4600 | 1720 | 2400 | 23 | 5080 |

| 6000 | 2400-3600 | 4900 | 1820 | 2425 | 24 | 6510 |

| 8000 | 3200-4800 | 5400 | 2020 | 2610 | 21 | 8360 |

| 10000 | 4000-6000 | 5800 | 2220 | 2852 | 19 | 11000 |

| 12000 | 4800-7200 | 6250 | 2320 | 3000 | 17 | 13100 |

| 15000 | 6000-9000 | 6600 | 2420 | 3150 | 17 | 14600 |

| 20000 | 8000-12000 | 7700 | 2750 | 3355 | 15 | 22000 |

| 25000 | 10000-15000 | 8200 | 2820 | 3500 | 13.4 | 24000 |

| 30000 | 12000-18000 | 8500 | 2970 | 3695 | 13.4 | 26250 |

-

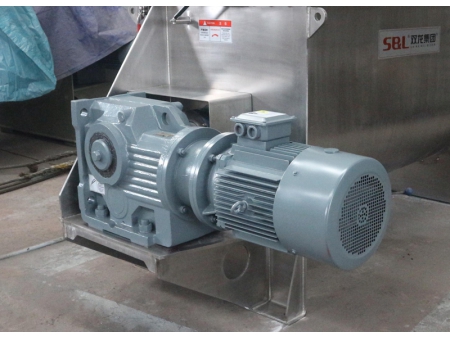

Drive unit

Standard horizontal mixers are driven by gear reducers through direct connection, which has the advantages of high torque, high reliability, and low noise. For large-scale equipment, a combination of gear reducers and belt transmission is adopted to protect the transmission components in case of unexpected situations. -

Flexibly detachable ribbon main shaft

The ribbon main shaft is connected to the drive shaft flange, allowing for quick disassembly when maintenance or replacement of the shaft is required. The flexible disassembly design enables the U-shaped vessel to be fully welded to the two end plates, avoiding material gaps that may occur with large flange connections on the vessel and reducing residue. -

Lip

Compared to other types of mixers, the horizontal ribbon mixer offers more flexibility in terms of the lip. It can be designed as fully open, half open, or fully sealed. The fully open design is suitable for situations that require high cleanliness standards and is supported by gas springs for convenient and safe operation. -

Discharge valve

Generally a pneumatic flipper valve is adopted. The circular arc valve is tightly embedded in the cylinder, flush with the inner wall of the cylinder, and free from the phenomena of material accumulation and dead corners for mixing. The reliable edge strip-type sealing ensures no leakage during frequent opening and closing. -

Heating/cooling jacket

Various types of jackets can be added to the outer body of the mixer, allowing for the cooling or heating of the material by injecting cold or hot media into the jackets. Cooling is typically achieved by pumping industrial water into the jackets, while heating can be achieved by introducing steam or thermal oil. -

Main shaft seal

When mixing ultrafine powders, the use of a new type of balanced seal and packing seal enhances the airtightness and effectively prevent the flow of gas and powder between the inside and outside of the vessel.

Ribbon Mixer with CIP

S&L horizontal ribbon mixers are able to achieve optimal performance for hygienic production by implementing a Clean-in-Place (CIP) system. This feature can be added to all of our models. CIP is an efficient cleaning process that requires some manual preparation steps, such as installing a washing device. Once installed, the system performs a complete cleaning in fully automatic mode through PLC technology. Drying with air is necessary after wet cleaning. With no cross-contamination between batches, you can be assured of the quality of your finished products.