Metal 3D Printer

Request a Quote

Printing materials:

Stainless steel, mold steel, high temperature alloy, etc.

Technical Specifications

| ltem | Unit | Specifications |

| Model | JIC-SLM440 | |

| Build volume | mm | 400*400*360 (with the basic plate) |

| Powder layer thickness | mm | 0.02-0.12 (adjustable) |

| Powder laying options | One-way, two-way slow and two-way fast | |

| Powder feeding method | Upside feeding | |

| Beam quality | M2≤1.05 | |

| Scan speed | m/s | Max. 10 |

| Scan system | Germany SCANLAB full sets | |

| Laser system | Germany IPG laser, 500W*1/2/4 | |

| Print speed | cm³/h | 25; 50; 100 |

| Minimum oxygen content | ppm | ≤100 |

| Protective gas | Nitrogen, Argon | |

| Operating environment | ℃ | 22-28, humidity ≤ 40% |

| Power consumption | kW | ≤ 20 (AC380V 3Ph/N/PE) |

| Machine dimensions | mm | 3200*1200*2500 |

| Gross weight | kg | About 2500 |

| Printing materials | Stainless steel, mold steel, high temperature alloy, etc. |

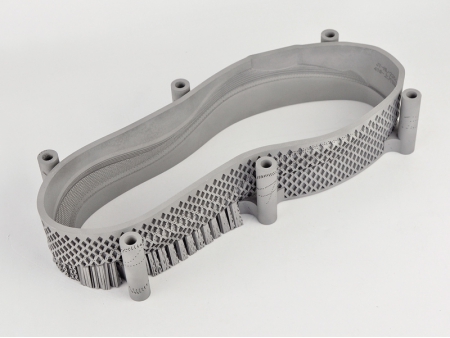

| Midsole Shoe Mold (ETPU process) | Print Time (per pair) | Single Mold Outer Dimensions (L × W × H) |

| | 16 hours/pair | 316 *142*61 mm |

| | 35 hours/pair | 335 *147 *112mm |

| RB Shoe Mold | Print Time (per pair) | Single Mold Outer Dimensions (L × W × H) |

| | 34 hours/pair | 298 mm × 148 mm × 41 mm (The bottom is partially hollowed.) |

| | 22 hours/pair | 305*137*34 mm (The bottom is solid) |

Note: Data based on JIC Machine test conditions. Actual results may vary depending on specific molds and processes used by customers.

Features

- Open Parameters: Fully accessible process settings and databases let users customize process packages to match diverse production needs.

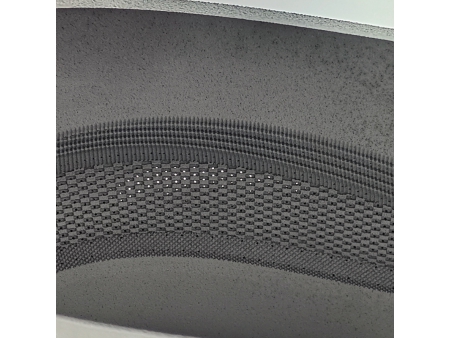

- High Precision & Smooth Finish: Advanced equipment and processes deliver dimensional accuracy within ±0.05mm, ensuring clear patterns and superior surface quality for all types of shoe molds.

- Exceptional Efficiency: Incorporates multi-layer printing, intelligent variable layer thickness (automatically adjusting layer thickness based on part geometry and production speed), shell removal printing (optimizing internal structures to boost efficiency and reduce material use), rapid double spreading (enabling simultaneous dual-layer powder spreading with dual laser heads), and intelligent scanning to significantly increase printing speed.

- Versatile Processes: Adaptable for diverse shoe mold designs, including midsole molds (ETPU process) with breathable holes as small as 0.1mm. Specialized breathable steel mold processes enable full breathability without visible holes, while maintaining precise patterns and a smooth surface finish.

- Excellent Cost-Performance Ratio: Built entirely with premium imported components for long-term stability and consistency, without cost-cutting simplifications. The machine uses widely compatible, affordable consumables for easy maintenance and reduced operating costs.