Metal Forming Machines

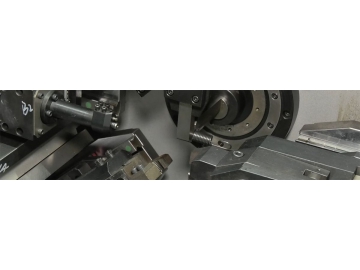

The metal forming machine adopts cold roll forming technology which is a highly efficient and economical processing method. The forming stations are assembled with definite shapes of rollers. As sheet metal travels between the forming stations, it is formed gradually into desired geometry.

For producing parts with long length or in large quantities, roll forming technology can do a good job. Our metal forming machine can produce a variety of cross- section profiles, while each profile requires a carefully crafted set of roll tools. Compared to extruded ones of similar shapes, roll formed sections have several advantages such as lighter weight and better strength, because they are processed in a cold state. In addition, the part can be produced with surface finish or even painted.

The roll forming machines being produced now are mainly for similar products such as stud and track profiles. Multiple configurations can be set up for different roll forming lines in order to punch and cut off parts in a continuous operation. If the process needs to cut a part to length, you can set up the lines to use a pre-cut die. While set up to use a post-cut die, the roll forming lines will cut off the profile at the precise position after the roll forming process.

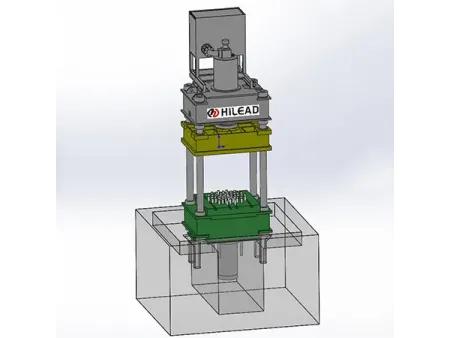

There are several kinds of metal forming techniques, but cold pressing forming, die-casting forming, and metal injection forming are the main types. The cold pressing forming is the most common one.

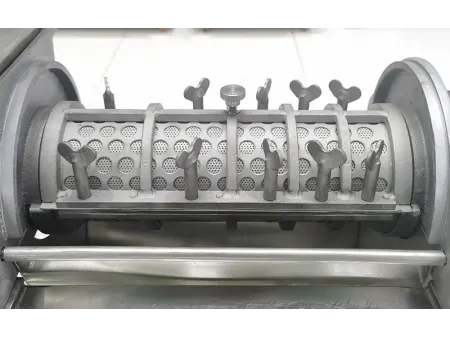

We have provided 6 different models of cold pressing metal forming equipment. Each of them can be used to produce different metal panels. The C/Z shaped steel purlin machine can produce C/Z shaped steel purlin, and it is very durable. The glazed tile corrugated roll forming machine can produce color glazed tile. It has the largest size among all the sheet metal forming machineries, which is 11,000×1,500×1,400mm, while the weight reaches 11.5 tons. The deck floor roll forming machine is specialized in producing structure deck with high efficiency and easy manipulation. The flat corrugated steel sheet roll forming machine and the double layer corrugated steel sheet roll forming machine are both used to produce corrugated steel sheet. The former one has smaller dimensions and produces smaller sheet, but they keep the basically same thickness of sheet produced. The spiral steel silo forming machine can produce silos of diameters ranging from 2.5m to 50m which are multifunctional. All of the metal forming machines are equipped with advanced PLC controlling system to bring convenience in your production.

As a specialized metal forming machine manufacturer in China, our company also offers KR-18B/KR-24 steel panel forming machine, guard rail forming machine, sandwich panel production line, among others.