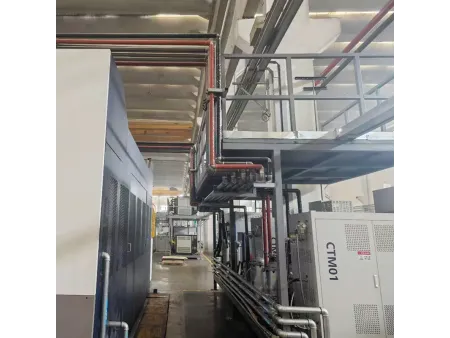

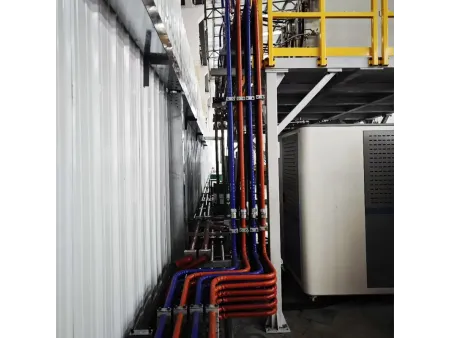

Integrated Piping System

Request a Quote

Fluid Control for Die Casting

Water purification system for providing pure cooling water used in die casting process

Integrated piping system connecting equipment to molds and between equipment, providing different water and oil circuits to achieve precise temperature control.

- Seamless connection reduces leakage risks: The integrated piping system uses one-piece die-cast main pipelines and standardized quick-connect components. The number of joints is reduced by 60% compared to traditional piping, eliminating leakage risks caused by assembly gaps or seal aging. Whether for high-pressure hydraulic lines or precision cooling circuits, it ensures long-term stable operation with “zero loss, zero interference” in medium transport.

- Fast installation for rapid production line setup: The integrated piping system is plug-and-play. All modules are pre-fabricated at the factory according to preset parameters, and on-site installation only requires alignment holes and connectors for assembly and fixing. Installation efficiency is improved by more than three times. For example, in a workshop producing 100,000 die castings annually, the installation cycle of the piping system can be reduced from 20 days to 5 days, helping production lines start earlier and generate profits faster.

- Full compatibility and flexible adaptation to production needs: Compatible with die casting equipment from different brands and various medium pressure levels. When expanding production lines or upgrading processes, you only need to add corresponding modules to extend the piping system, reducing transformation costs by 50%. From compact space utilization to safety and reliability, from fast installation to flexible adaptation, the integrated piping system with its “integrated thinking” resolves many pain points of traditional piping. It is not just a hardware system for medium transport but also a strategic tool to optimize workshop management and enhance production resilience.

Parameters

| Cost Type | Traditional Distributed Piping | Integrated Piping | Cost Savings Range |

| Consumable Cost | Many joints and valves, easy to wear, frequent replacement | Integrated modules reduce joints/valves, improved durability | Annual consumable costs reduced by 30%–40% |

| Energy Cost | Distributed piping causes large pressure loss (hydraulic/pneumatic systems need higher compensation), uneven cooling water flow causes energy waste | Shorter and more compact piping layout reduces pressure loss by 15%–25%, optimized cooling system energy consumption | Annual energy costs reduced by 10%–20% |

| Maintenance Cost | Distributed piping requires segment-by-segment inspection and maintenance, high labor cost | Centralized inspection fast fault location reduces manual maintenance workload | Annual maintenance labor costs reduced by 40%–60% |

| Space Cost | Distributed piping occupies workshop floor/ceiling space, affecting logistics | Centralized layout (e.g., integrated along equipment columns/ceilings) frees up workshop space | Workshop utilization rate increased by 5%–10% |