PCD Diamond Saw Blade

SERIES 1

- Selecting suitable materials Avoid using PCD diamond saw blades on solid hardwoods with numerous knots (such as pine) as it can damage the blade. For composite boards with excessive impurities like stones or nails (e.g., particle boards), handle with care during use.

- Regular cleaning for longevity If you notice increased cutting resistance, higher noise levels, material darkening, or saw teeth sticking to glue, promptly remove and clean the blade. Soak the blade in a rust-inhibiting or alkaline solution for about an hour, then scrub the teeth and surface with a brush.

- Handle with care Since diamond is highly hard yet brittle, it's prone to chipping. Take extra care when handling, transporting, and mounting the blades to avoid damage from knocks or impacts.

- Routine inspection and sharpening Regularly check for signs of worn or chipped teeth and glue buildup. Sharpen the blade as needed to maintain optimal performance. Based on extensive experience, sharpening the blade after a fixed number of cuts ensures it functions at maximum efficiency.

Designed for cutting particleboard materials efficiently, this PCD circular saw blade can also be used effectively for processing panel furniture and MDF composite boards. Compared to carbide-tipped saw blades, the PCD blade offers 20 to 50 times longer service life, significantly reducing blade replacement frequency and boosting operational efficiency. Its durability makes it a go-to choice for woodworking applications that demand high productivity and cost-effective performance.

Suitable for processing aluminum sheets, extrusions, doors, windows, rods, and radiators, the PCD circular saw blade offers 20 to 50 times the service life compared to traditional carbide-tipped blades. Its excellent hardness and wear resistance minimize the need for frequent replacements and reduce maintenance downtime.

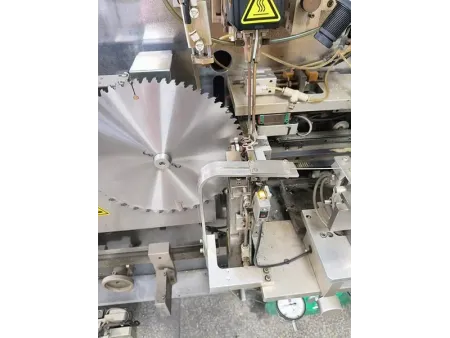

Ideal for sliding table saws, PCD circular saw blade is ideal for precise and efficient cutting of engineered wood panels, including furniture boards, MDF, particleboard, and other composite materials. With its high durability and superior edge retention, the blade delivers consistently smooth cuts, reducing the frequency of blade replacements and ensuring reliable performance for long-term use.

The PCD circular saw blade is designed for processing high-density materials like compact laminate boards, calcium carbonate panels, and layered phenolic boards. These circular saw blades offer a service life that is 20 to 50 times longer than traditional carbide-tipped blades, thanks to their superior hardness and wear resistance, making them an ideal choice for efficient and consistent cutting of tough materials.

This PCD circular saw blade is designed to be used with wood trimming machines in the woodworking industry. It is ideal for processing panel furniture, MDF boards, particleboards, and other composite panel materials, delivering superior durability and cutting efficiency.

PCD circular saw blades are widely used in the woodworking industry, specifically for manufacturing speaker enclosures. They effectively processes MDF boards, particleboards, and other composite panel materials, delivering precise cuts and long-lasting durability for high-quality speaker production.

Designed for use in multi-blade saw machines within the woodworking industry, this PCD circular saw blade is highly effective for cutting MDF boards, particleboards, and composite panels used in furniture manufacturing. Compared to traditional methods, it offers significantly higher efficiency and enhanced precision, making it ideal for large-scale woodwork production.

The PCD scoring saw blade is designed for precise grooving and scoring in the woodworking industry making it suitable for processing panel furniture, MDF boards, particleboards, and composite panels.

The PCD grooving saw blade is designed for chip-free grooving tasks in woodworking applications, ideal for processing solid wood and other wood-based composite panels, particularly in edge banding machines. The polycrystalline diamond-tipped edges of this grooving saw blade ensure consistent and clean grooves, enhancing the quality of subsequent finishing processes.