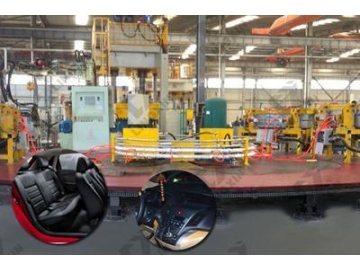

PU Foam Machine for Car Seat

The PU car seat production line is primarily used in the manufacturing of polyurethane seats and armrests, including car seats, armrests, motorcycle seats, and other vehicle seats and arm rests. The PU foaming machine is compatible with 141B foaming and a water foaming system.

| Raw material viscosity (22℃) | Polyhydric alcohol: 2000MPas |

| Polyisocyanate: 1000MPas | |

| Injection pressure | 10~20MPa(ADJ) |

| Mix ratio | 1:5~5:1 (ADJ) |

| Injection time | 0.5~99.99 S (Accurate to 0.01 S) |

| Material temperature control error | ±2℃ |

| Repeated injection accuracy | ±1% |

| Injection flow rate | 160-800g/s |

| Hydraulic system pressure | 10~20MPa |

| Volume of tank | 250L |

| Compressed air consumption( dry and no oil) | P: 0.7MPa |

| Q: 600NL/min | |

| Production line operation speed | 3-10m/min |

| Input voltage | three-phase five-wire, 380V |

- Main engine of PU foaming machine

- Seat mould

- Hydraulic-Pressure Unit System

- Korea SPU high efficiency mixing head

- High-end metering pump

- Metering pump motor

- Feed pump

- Water chiller

- Raw material tank

- Raw material filter

- Schneider AC contactor

- Taiwan AirTAC cylinder

- High quality magnetic coupling

- PLC controlling system

- Operation panel

1. The high precision plunger variable pump is accurate and steady.

2. This feeding program provides 100 stations, with every station able to be programmed to meet the production needs for multiple products.

3. The mixing head used for injection can freely move in 6 directions, including front/back, left/right, and up/down. The double close switch control ensures accurate injection.

4. The high precision mixing head is made of a high strength material with a service life of more than 500,000 uses. High pressure injection and impact mixing produce a high mixing uniformity, and the self-cleaning function ensures there is no residue, and no need to clean or maintain the equipment.

5. The pressure needle valve uses two raw material types (polyisocyanate and polyhydric alcohol) and will automatically lock when they balance, ensuring the pressure between the two raw materials is consistent.

6. Magnetic coupling uses a permanent magnet control which avoids temperature rises and leaks.

7. The raw material timing cycle function ensures the raw materials do not crystalize when the equipment is not in use.

8. A fully digitized and modularized integration system controls all technological process, which is visualized, precise and safe to operate.

This is the product model table for customers to use in product selection. If you do not find what you want or need, contact Lingxin directly, and we will customize polyurethane equipment to meet your needs.

LXPU-CS-24 PU Foam Machine for Car Seat| Foam type | Injection flow rate( mix ratio =1:1) | Mixing head | Polyether polyol metering pump | Isocyanate metering pump | Volume of tank | Total power | Input voltage |

| Flexible foam | 160-800g/s | Korea SPU | A2VK-28 | A2VK-12 | 250L | 45KW | 380V 50Hz |

Index

PU equipment, automotive foam seats, PU foam production line