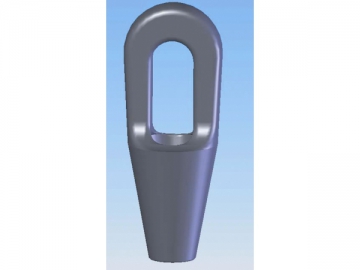

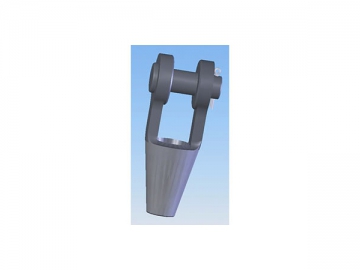

Spelter Socket (Open and Closed)

This is a connector mounted on the end of the rope. One end of a hollow cone is used for insert ing the cable end and pouring fastening. The other end is an eye thimble of the eye ring or fork.

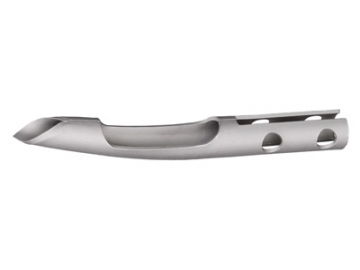

Material: alloy steel integral forging

Processing: CNC machining center

Safety factor: 4 times

Surface: Black painting or zinc plating

| ltem No | Rope Diameter | Dimensions(mm) | ||||

| L | B | A | D | D1 | ||

| TH2501 | 10.5 | 144 | 29 | 45 | 14 | 20 |

| TH2502 | 12 | 159 | 31 | 49 | 16 | 22 |

| TH2503 | 14 | 176 | 31 | 53 | 18 | 24 |

| TH2504 | 16 | 193 | 32 | 58 | 20 | 26 |

| TH2505 | 18 | 210 | 35 | 65 | 23 | 29 |

| TH2506 | 20 | 227 | 37 | 73 | 25 | 32 |

| TH2507 | 22.5 | 245 | 40 | 80 | 30 | 35 |

| TH2508 | 24 | 262 | 44 | 88 | 32 | 38 |

| TH2509 | 25 | 281 | 48 | 96 | 33 | 41 |

| TH2510 | 28 | 298 | 51 | 103 | 36 | 44 |

| TH2511 | 30 | 316 | 54 | 110 | 38 | 47 |

| TH2512 | 31.5 | 335 | 56 | 118 | 40 | 50 |

| TH2513 | 33.5 | 353 | 59 | 125 | 42 | 54 |

| TH2514 | 36 | 373 | 62 | 132 | 44 | 57 |

| TH2515 | 37.5 | 392 | 66 | 138 | 47 | 60 |

| TH2516 | 40 | 413 | 70 | 146 | 49 | 63 |

| TH2517 | 42 | 434 | 72 | 152 | 52 | 66 |

| TH2518 | 45 | 474 | 79 | 167 | 54 | 72 |

| TH2519 | 47.5 | 494 | 82 | 174 | 57 | 75 |

| TH2520 | 50 | 516 | 85 | 181 | 60 | 78 |

| TH2521 | 53 | 536 | 89 | 189 | 63 | 81 |

| TH2522 | 56 | 567 | 93 | 199 | 66 | 85 |

| TH2523 | 60 | 619 | 101 | 215 | 70 | 92 |

| TH2524 | 63 | 641 | 105 | 221 | 74 | 95 |

| ltem No | Rope Diameter | Dimensions(mm) | |||||

| L | L1 | B | C | D | H | ||

| TH2251 | 10.5 | 144 | 63 | 32 | 15 | 14 | 18 |

| TH2552 | 12 | 159 | 69 | 34 | 17 | 16 | 20 |

| TH2553 | 14 | 176 | 76 | 37 | 19 | 18 | 22 |

| TH2554 | 16 | 193 | 84 | 40 | 21 | 20 | 24 |

| TH2555 | 18 | 210 | 91 | 43 | 24 | 23 | 27 |

| TH2556 | 20 | 227 | 98 | 47 | 26 | 25 | 30 |

| TH2557 | 22.5 | 245 | 105 | 52 | 29 | 30 | 33 |

| TH2558 | 24 | 262 | 112 | 56 | 31 | 32 | 36 |

| TH2559 | 25 | 281 | 120 | 60 | 34 | 33 | 39 |

| TH2560 | 28 | 298 | 127 | 65 | 36 | 36 | 41 |

| TH2561 | 30 | 316 | 134 | 68 | 39 | 38 | 44 |

| TH2562 | 31.5 | 335 | 142 | 72 | 42 | 40 | 47 |

| TH2563 | 33.5 | 353 | 150 | 75 | 44 | 42 | 50 |

| TH2564 | 36 | 373 | 158 | 80 | 47 | 44 | 53 |

| TH2565 | 37.35 | 392 | 168 | 84 | 47 | 47 | 56 |

| TH2566 | 40 | 413 | 175 | 88 | 52 | 49 | 59 |

| TH2567 | 42 | 434 | 184 | 92 | 54 | 52 | 61 |

| TH2568 | 45 | 474 | 200 | 101 | 60 | 54 | 67 |

| TH2569 | 47.5 | 494 | 209 | 104 | 62 | 57 | 70 |

| TH2570 | 50 | 516 | 218 | 109 | 65 | 60 | 73 |

| TH2571 | 53 | 536 | 227 | 113 | 67 | 63 | 76 |

| TH2572 | 56 | 567 | 240 | 119 | 71 | 66 | 80 |

| TH2573 | 60 | 619 | 262 | 129 | 78 | 70 | 87 |

| TH2574 | 63 | 641 | 271 | 133 | 81 | 74 | 90 |

Scrap Standard:

The body has any obvious permanent deformations.

Larger than 10% of the section wear is worn out according to the original size *Any crack on body.

Tensile test failed.

Production process:

Round billet inspection---cutting---Die forging--- Roughly machining ---heat treatment---grinding shot blasting --- Numerical control machining --- assembly---tensile testing---surface coating ---storage

Packing:

Packed in wooden cases

Other search items: wire rope fittings