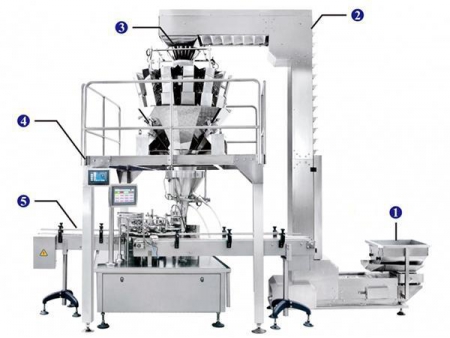

Automatic Jar Filling and Sealing Line, 10 or 14 Head Weigher

- Vibratory feeder

- Z-shaped elevating conveyor

- Multihead weigher

- Working platform

- Auto jar filling equipment

The automatic jar/bottle filling and sealing line is composed of auto jar/bottle filling equipment, working platform, Z-shaped elevating conveyor, multihead weigher and vibratory feeder to finish fully automatic feeding, weighing, filling, sealing, capping, date printing and labeling processes.

We have two typical jar filling methods for customers to choose from: a single jar mold or a two jars in one mold, allowing users to use different types based on their jar filling methods.

Jar types

| Model series | Standard configuration | Maximum jar filling and capping speed (jar/min) | Maximum jar weight |

| Single jar mold | 10 heads weigher | 40j/min | 1000g |

| Two jars in one mold | 14 heads weigher | 70j/min | 800g |

- Check weigher

- Metal Detectors

- Combined metal detector and check weigher

Inserting equipment: Designed to insert small bags of sorbent, desiccant, seasoning mix and more.

Electromagnetic induction aluminum foil sealer: The jar/bottle is sealed with aluminum foil, making this equipment applicable to products with requirements for a tighter sealing. Usually works in conjunction with insertion equipment.

Labeling machine: Stick labels on the jar/bottle, you can choose to stick on one side, double sides, circular or other forms.

Diverter chute: Fill your products in multiple dispersing spouts to be ready for more than 1 jar filling, use the 2 jars in 1 mold if you are filling 2 jars at the same time, use 4 in one mold if you are filling 4 jars a time, and so on.