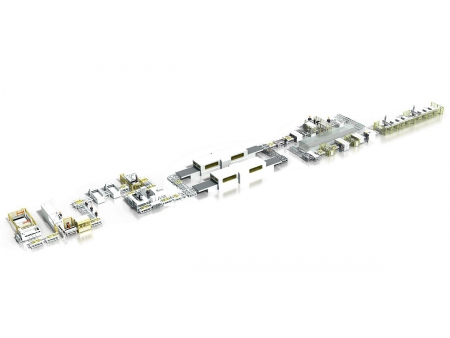

Rockwool Sandwich Panel Production Line

When it comes to rockwool sandwich panel production lines, TONGFENG would be your best choice. The sandwich panel is an innovative structural element comprising flat sheet metal faces (usually steel) with a rigid core bonded to both faces. Cores can be made of lightweight and non-combustible materials, e.g. foamed-glass, rockwool, polystyrene etc.

The mineral-wool sandwich panel line is well-suited for construction of industrial workshops, warehouses, cold rooms, ship cabins and other projects. It provides high flexibility when applied in all kinds of buildings.

Benefits of the Rockwool Sandwich Panel Production Line

1. Light weight: 10-14 kg/m2, equal to one thirtieth of that of the brick wall

2. Superior thermal insulation: 0.035W/mK thermal conductivity

3. High mechanical strength: The sandwich panel system can be used as the load bearing structure or external envelop of the building. It has the capability to resist tension and compression.

4. Vivid colors: Surface decoration is not required.

5. Easy to assemble: The construction period is down 40%.

Technical Data of the Rockwool Sandwich Panel Production Line

| Overall Dimension of the Metal Insulated Panel Production Line | 32000mm ×3600mm×3300mm |

| Electrical Control System | PLC-based industrial computer control system with a variable-frequency drive |

| Total Power (including heating power) | Approximately 30KW |

| Working Speed | 1000~4000mm/min. (frequency control) |

| Density of EPS Panel | >18KG/mmm |

| Suitable Material | 1000~1200mm × (0.5~0.6mm) foam |