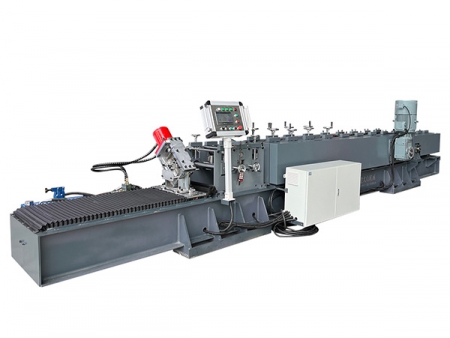

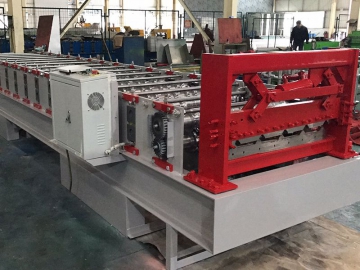

Car Body Panel Roll Forming Machine

The car body panel roll forming machine is composed of a feeding cart, an uncoiler, a flattener, a changeover device, a feedstock guiding system, a roll former, a spot welding system, a straightening unit, a flying saw, a telescopic discharge unit and an automatic control system. It is built to produce a wide range of beautiful panels for the construction of cars and shipping containers etc.

This automotive components manufacturing equipment is featured by a high level of automation, easy operation, long lifespan, precise sizing performance, and extremely high utilization rate of raw materials. It is ideal for roll forming of wide panels.

Characteristics of the Car Body Panel Roll Forming Machine

1. The entire rollforming equipment features an H-beam structure design. It provides the advantages of simple structure, great loading capacity and exceptionally reliable performance.

2. Low noise and ultra-high work efficiency

3. Automated cut-to-length and precise positioning process helps to protect the car body panels from deformation.

4. Every piece of sheet metal is cut at a precision of less than 0.1mm.

5. A lubrication system is provided to lube the bearings, gear mechanisms, guide rails and other parts automatically when the machine is running.

6. The automotive roll forming line is suitable for cold roll forming of galvanized or color-coated steel coils with a maximum width of 1,200mm. Typical applications are in steel structures, decoration, automobile and environmental protection industry etc.

Technical Parameters of the Car Body Panel Roll Forming Machine

| Capacity | Width: 400-800mm, Sheet thickness: 1.0-2.0mm |

| Production Speed | 0-15m/min. |

| Total Power | Approximately 35.5kW |

| Production Area (L×W) | 18m ×3m |

| Voltage | 380V/415V |

| Frequency | 50Hz |