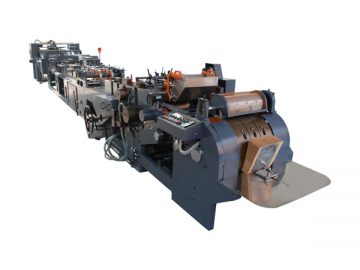

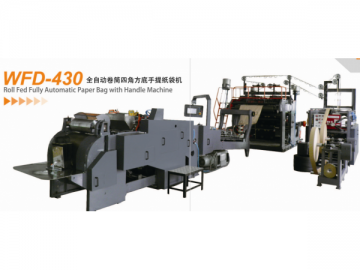

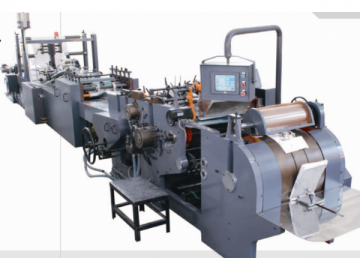

Paper Carrier Bag Machine

Our paper carrier bag machine owns suchhigh performance that any user will be impressed. It can meet specialmanufacture need such as making trapezoid bag. The machine increases theadjustable range of the paper dimension to produce bigger size paper bag thanour square bag maker.This bag making facility is equipped with an automatic paper loader which canstore paper so the machine can be fed continuously and labor cost can be saved.In addition the carrier bag manufacturing machine owns PLC and touch screen HMIwhich can ensure the preciseness and speed of production.

we believe the machine will no doubt become your idealpartner in business.

This material paper is fed by sheet. Once the sheet is fed, the ruler devicewill fix the location of paper. Then the paper will pass through pressureroller, gluing device which can use hot melt glue, forming device, organ edgefolder and tube maker. Afterwards the paper will be pushed into finishing linewhere it will be stretched, bottom formed and glued. Ultimately the paper ismade into a bag.

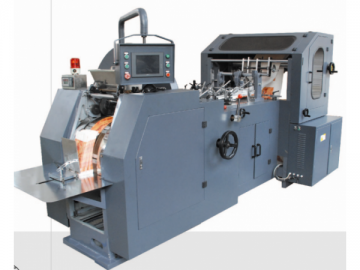

MainTechnical Parameter

| Maximum Speed (bag/min.) | 120 |

| Total Power (kw) | 16 |

| Machine Weight (Ton) | 11 |

| Machine Dimension (L*W*H) | 12500*2200* |

| Paper Roll Width (mm) | 505-1185 |

| Maximum Paper Roll Width (mm) | 1500 |

| Paper Weight (g/㎡) | 70-150 |

| Bag length (mm) | 280-600 |

| Bag Width (mm) | 160-430 |

| Bag Bottom Width (mm) | 80-175 |