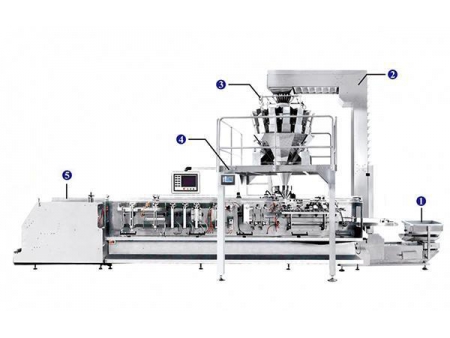

JW-JDC3 Pouch Bagger with Combination Scale, 14 heads weigher

- Vibratory feeder

- Z-shaped elevating conveyor

- 14 heads weigher

- Working platform

- Horizontal pre-made bag packing machine

The JW-JDC3 pouch bagger with a multihead weigher is our most efficient pre-made pouch packaging line, and features a maximum packaging speed of 120 bags per minute. This production line is composed of the horizontal pre-made bag packing machine, working platform, 14 head combination weigher, Z-shaped elevating conveyor and vibratory feeder in order to automatically complete the entire feeding, weighing, filling and sealing, label printing and discharging process.

Our most efficient pre-made pouch packaging line is great for clients with higher requirements for production output and efficiency, and we guarantee the best equipment quality.

Re-made bag packaging materials: Paper-plastic composite, plastic-plastic composite, aluminum-plastic composite, PE composite, multilayer composite, silicon dioxide film, aluminum foil, single layer PE, PP material and more.

Pouch types: 3 side seal pouches, 4 side seal pouches, flat pouches, flat pouches with zipper, stand-up pouches, stand-up pouches with zipper, shaped stand-up pouches, shaped flat pouches and more.

| Packaging speed | 120 P/M |

| Single weighing range | 10-1500g |

| Film width | 180-520mm |

| Film thickness | 0.04mm-0.15mm |

| Packing machine power | 3.4KW |

| Packing machine voltage | 220V |

| Multihead weigher power | 1500W |

| Multihead weigher voltage | 220V |

Note: The provided parameters are for reference only, and we can manufacture pre-made pouch baggers with a combination weigher according to your product types, weighing range, factory area and output.

- Check weigher

- Metal Detectors

- Combined metal detector and check weigher

- Thermal Transfer Overprinter

- Count verification machine

- Conveyor equipment

- Accessories