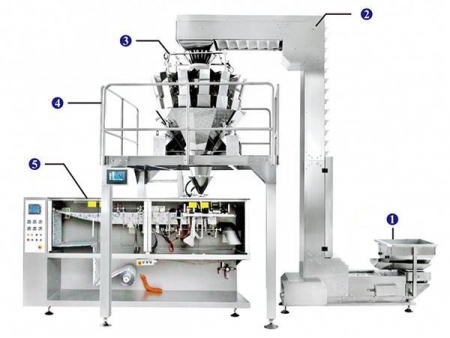

JW-JDC4 Preformed Bagger with 12 heads weigher

- Vibratory feeder

- Z-shaped elevating conveyor

- 12 heads weigher

- Working platform

- Economic horizontal pre-made pouch packaging machine

The JW-JDC4 preformed bag packaging line with combination weigher is composed of an economic horizontal pre-made pouch packaging machine, working platform, 12 heads weigher, Z-shaped elevating conveyor and vibratory feeder in order to automatically finish the entire feeding, weighing, filling and sealing, label printing and discharging process.

This production line not only occupies less floor space but is also much less expensive. It is ideal for customers with stricter requirements for production output and efficiency.

Re-made bag packaging materials: Paper-plastic composite, plastic-plastic composite, aluminum-plastic composite, PE composite, multilayer composite, silicon dioxide film, aluminum foil, single layer PE, PP material and more.

Pouch types: 3 side seal pouches, 4 side seal pouches, flat pouches, flat pouches with zipper, stand-up pouches, stand-up pouches with zipper, shaped stand-up pouches, shaped flat pouches and more.

| Packaging speed | 65 P/M |

| Single weighing range | 10-1500g |

| Film width | 180-520mm |

| Film thickness | 0.04mm-0.15mm |

| Packing machine power | 3.4KW |

| Packing machine voltage | 220V |

| Multihead weigher power | 1200W |

| Multihead weigher voltage | 220V |

Note: The provided parameters are for reference only, and we can manufacture the pre-made pouch bagger with a multihead weigher according to your product types, weighing range, factory area and output.

- Check weigher

- Metal Detectors

- Combined metal detector and check weigher

- Thermal Transfer Overprinter

- Count verification machine

- Conveyor equipment

- Accessories