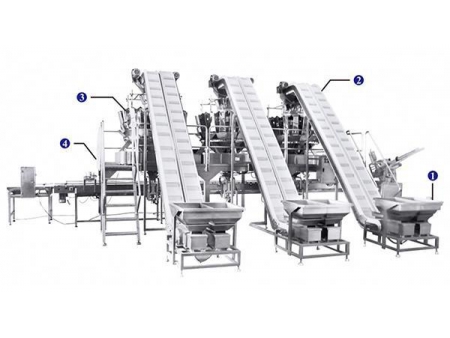

Automatic Tray Sealer

- Vibratory feeder

- Inclined feeding conveyor

- 14 heads weigher

- Working platform

The automatic tray sealer with a 14 heads weigher is composed of the vibratory feeder, inclined feeding conveyor, 14 heads weigher and working platform. This tray production line is used to automatically carry out the feeding, weighing, filling, sealing, label printing and sticking processes, and is specially designed for tray packaging of granules, pieces, strips, round, or irregularly shaped products, including candies, seeds, pet foods, puffed foods, hardware, rubber parts and more.

| Model series | Standard configuration | Maximum tray filling and sealing speed (tray/min) | Maximum tray weight |

| Single tray mold | 10 heads weigher | 35t/min | 1000g |

| Two trays in one mold | 14 heads weigher | 60t/min | 800g |

Note: Kenwei provides custom tray filling and sealing lines if you have specific requirements.

- Check weigher

- Metal Detectors

- Combined metal detector and check weigher

- Accessories

Inserting equipment: Designed to insert small bags of sorbent, desiccant, seasoning mix and etc.

Labeling machine: Stick labels on the tray box, you can choose to stick on one side, double sides, circular or other forms.

Diverter chute: Fill your products in multiple dispersing spouts to be ready for more than 1 tray filling, use the 2 trays in 1 mold if you are filling 2 trays at the same time, use 4 in one mold if you are filling 4 trays a time, and so on.