Technical Parameters

| Model | LHE-1000 | LHE-2000 | LHE-3500 | LHE-5000 |

| Production capacity (kg/h) | 400~1000 | 800~2500 | 1500~4000 | 3000~8000 |

| Main motor power (Kw) | 90 | 160/180 | 220/250 | 315/355 |

| Effective volume (L) | 1100 | 2100 | 3800 | 5400 |

Performance Advantages

LHE wet ultrafine grinding machine is the newly-developed grinding equipment of our company. Designed with totally-new machine structure, optimized machinery size, uniquely- designed machinery parts, and simplified production process, this wet ultrafine grinding machine has higher performance. Its advantages include:

- High efficiency

For producing the same amount of material, this wet ultrafine grinding machine consumes 30% less energy in comparison with conventional grinding equipment. - High fineness of finished products

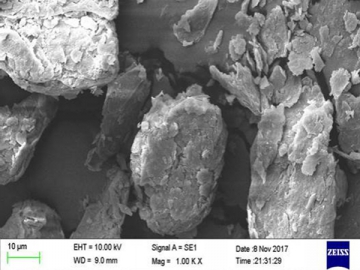

The size of grind-need material ranges from 200mesh to 325mesh, and the finished material fineness is 2μm. - The parts inside the grinding machine are made of high hardness, wearing-resistant materials. Hence, the grinding machine features long service life.

- The starting torque is low, and as a result the grinding machine produces a small impact on power grid.

- The finished material has a low temperature, low viscosity, and good fluidity.

- The wet ultrafine grinding machine can be used independently or used in combination with each other.

- Fully automatic controlled, easy to operate, and the production capacity is stable.

- Low loss of grinding medium, and as a result, there is no pollution on materials.

Working Principle

Firstly, the wet material will be pumped into the grinding machine which is prepared with a certain amount of grinding mediums. Then, the driving part will drive the mixing parts to rotate in a high speed. Due to this, the wet materials and grinding mediums will also rotate at a high speed, thus the raw materials will be ground into ultrafine materials under the impact force, shearing force and collision force between grinding mediums.

Finally, the ultrafine materials will be filtered by the vibrating screen, and then will be discharged from the discharging hole and collected by the collection system.

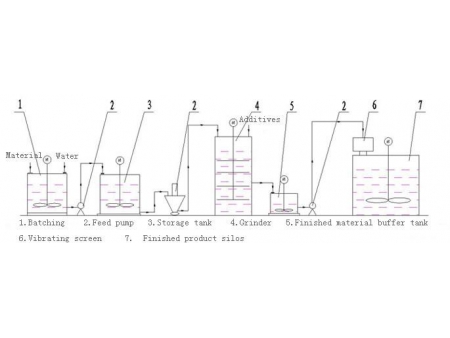

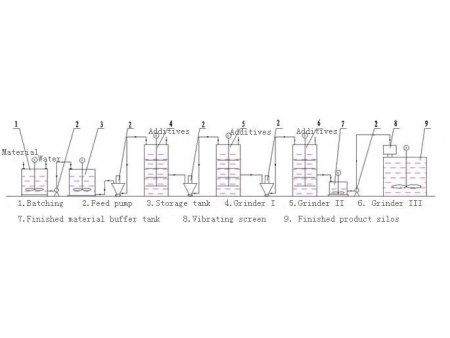

Process Flow