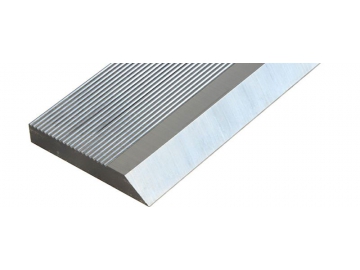

SF-380S/405S Type Fingerless Single Facer For Corrugated Paperboard

SF-380S/405S Type Fingerless Single Facer For Corrugated Paperboard

Designed speed: SF-380S:

Effective width:

Corrugating roll diameter: SF-380S:

1. The corrugating rolls for the fingerless single facer can be integrally mounted and dismounted, which ensures convenient and simple corrugating roll exchanging. They are all controlled by air springs, which assures more stable output, lower vibration, and longer service life, as compared with rollers controlled by conventional air cylinders or oil cylinders.

2. Made of quality 48CrMo alloy steel, all the corrugating rolls are given heat treatment to offer hardness between HRC58° and HRC60°. Chrome plating provides them better abrasion resistance and longer service life. Also, the roller surfaces are fine polished.

3. Vacuum suction type web guide method, coupled with air flow adjustment function, guarantees stable flute forming at even high speed working conditions.

4. Oil bath lubrication method for the enclosed gear transmission system achieves reduced operation noise, smooth operation, and extended gear lifespan.

5. The high temperature grease makes sure the bearings for the corrugating rolls and pressure rolls have long service life, and smoother operation.

6. This range of fingerless single facer for corrugated paperboard incorporates linerboard preheating rolls, and a medium paper conditioner.

7. Mounted on the same base, the glue-coating rollers and glue-thickness control rollers can be conveniently assembled and disassembled from the machine synchronously, which assures easy maintenance.

8. The machine adopts a variable frequency motor for main drive, an independent driving box, and a three-shaft driving system. Also, it uses a variable frequency drive for speed control. These designs make the equipment energy efficient, and also ensure convenient control and production management.

9. The fingerless single facer is designed with an enclosed gear transmission system which uses oil bath lubrication method. This guarantee reduced noise, smooth operation, and extended gear lifespan.

10. The gluing unit comes with an electrical gluing width control system, and is able to run independently when the main machine stops working. Thus, it can effectively prevent drying of the adhesive. Electrical and manual adhesive thickness adjustment methods are both available.

Related Names

High Speed Corrugated Paperboard Making Machine | Durable Single Facer Machine