Fixed Type Single Facer

Request a Quote

Corrugated Board Manufacturing

Universal joint drive

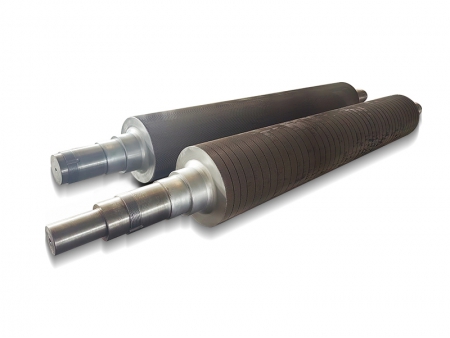

Corrugated rollers

| Max. Machine speed | 100m/min |

| Heating method | Steam, electricity, oil |

| Temperature range | 160-200℃ |

| Steam pressure | 0.8-1.3MPa |

| Flute type | U, V or UV |

| Corrugated roller diameter | Ø280mm |

| Glue roller diameter | Ø216mm |

| Preheater diameter | Ø320mm |

| Pressure roller diameter | Ø284mm |

| Fixed paste roller diameter | Ø110mm |

Features

- Paper feeding is carried out by using vacuum absorption method, a high-pressure blower is equipped to ensure the stable corrugation process at high speed;

- The width of groove on lower corrugating roll is less than 2mm, efficiently preventing the marks of stripes on corrugated cardboard;

- Universal joint transmission system is adopted to reduce vibration, enabling the operation more stable and reliable;

- Reduction gearbox is designed with oil-immersed lubrication to lower the machine vibration;

- Automatic glue feeding, pneumatic control of glue application and return can provide cushion effect;

- Engraved glue applicator roll is chrome plated;

- The glue width is electrically adjusted with convenience and fastness;

- The surface of glue applicator roll is engraved and chromium-plated;

- When the single facer is heated by steam, paper medium can be equipped with a water sprayer which is able to humidify paper and avoid paperboard bursting, ensuring the forming of paper medium and improving the smoothness and production speed of corrugated board.

Other Products You May Like