Learn More About Sicheng Abrasives

Founded in 1999, our factory has been specializing in abrasive production for over 20 years. Covering an area of 7,500 square kilometers, our monthly production capacity reaches 8,000 tons.

Our facility is well-equipped with various departments including raw material storage, smelting, cooling, sand production, micro powder production, quality inspection, and finished product storage. This comprehensive setup allows for efficient operations and high-quality service to our customers.

Our experienced sales team, with nearly 20 years of expertise, and over 30 skilled production workers have established strong partnerships with clients in over 60 countries and regions, delivering high-quality products for more than two decades. To prevent dust pollution during production, our factory is equipped with advanced dust removal systems, reducing energy consumption while ensuring the health of our employees and protecting the environment.

-

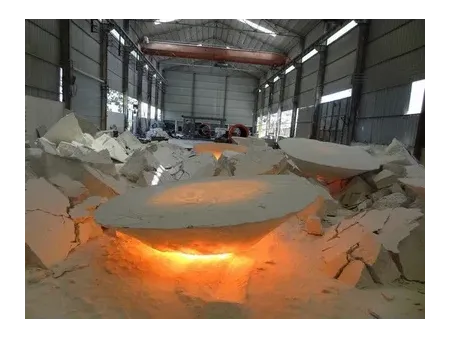

Smelting furnace

Smelting aluminum oxide at a high temperature of 2200°C.

-

Fixed furnace, water cooling

After high-temperature smelting, rapid water cooling is

-

Overhead crane

Facilitates the loading, unloading, and transportation of heavy materials during production.

-

Jaw crusher

Used for medium-sized crushing of large materials.

-

Elevator

Transports materials to higher levels for further processing operations.

-

Magnetic separator

Separates magnetic materials from non-magnetic materials.

-

Ball mill

Used for crushing and mixing materials.

-

Screening equipment

Sorts products into different sizes.

-

Overflow tank

Uses water buoyancy to control timing and extract products of different sizes.

-

Settling tank

Products of the same size extracted are placed in the settling tank, allowing them to settle before removal, facilitating the subsequent drying operation.

-

Dust extraction equipment

Removes dust from the workshop for easier handling in later stages and to prevent environmental impact.

-

Drying room

Used for drying the settled fine powder after precipitation.

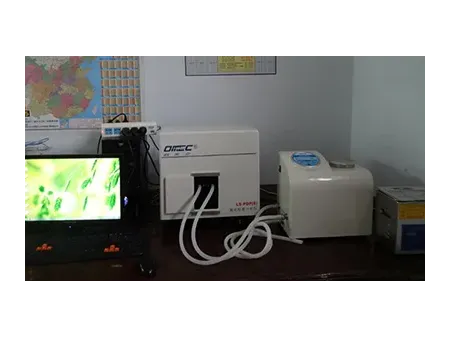

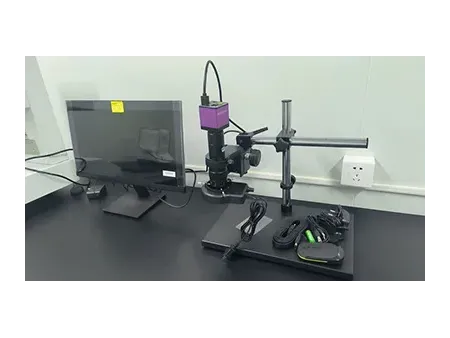

Our company operates production in accordance with the international abrasive standard system, implementing stringent quality testing at every major production stage. Additionally, we have a dedicated inspection laboratory equipped with advanced testing and experimental equipment, along with professional testing personnel. Quality inspection and testing are conducted based on international abrasive standards, ensuring thorough examination of each batch of goods during production, with further testing before shipment to confirm compliance before release to customers. Our range of professional testing instruments includes OMEC laser particle size analyzers, burettes, impact sieves, microscopes, density testers, and other advanced testing equipment.

Standard Fractional Sieve

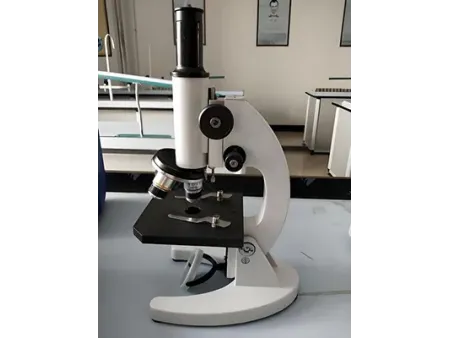

Standard Fractional Sieve  Microscope

Microscope

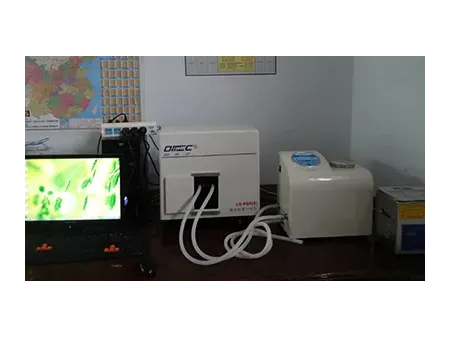

OMEC Laser Particle Size Analyzer

OMEC Laser Particle Size Analyzer  Electrical Resistance Particle Counter

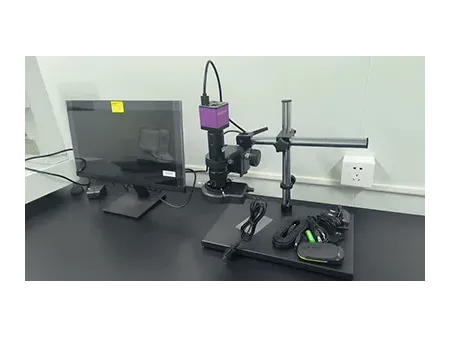

Electrical Resistance Particle Counter  4K Ultra HD Electron Microscope

4K Ultra HD Electron Microscope