Capabilities

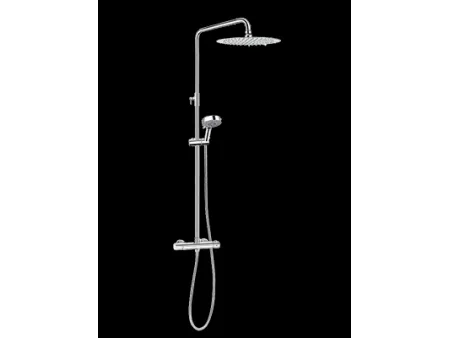

Circa 1995, KOLEGO has been a premier provider of exquisite faucets, catering to discerning clients with a sophisticated range of kitchen, bathroom sink, shower, and bathtub faucets.

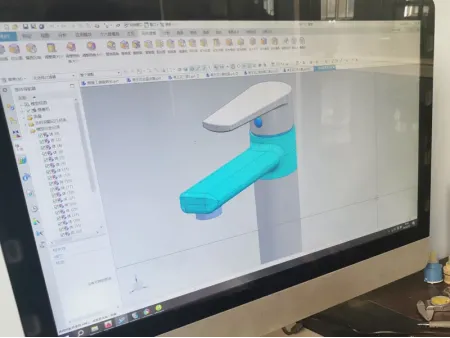

Unparalleled Design and CraftsmanshipAt KOLEGO, we excel in bespoke faucet design, offering an array of luxurious materials, finishes, sizes, and handle designs tailored to complement your interior aesthetics. Our commitment to quality is unwavering, with each faucet undergoing rigorous testing, including leak assessments, coating integrity checks, valve durability tests, and braided hose strength evaluations.

Our legacy of excellence is reflected in long-standing partnerships that span over 15 years. For those seeking to wholesale faucets that epitomize elegance and functionality, KOLEGO stands as your ultimate partner, dedicated to transforming your spaces with timeless luxury and precision.

Raw Material Warehouse

At KOLEGO, we utilize Grade A copper ingots to ensure our faucets are crafted from high-quality, low-lead copper. Our copper boasts over 59% purity with lead content below 1.5%.

Uncompromising quality assurance, every batch of copper ingots is accompanied by a supplier's Spectro analysis report. Before acceptance into our production line, KOLEGO conducts its own meticulous Spectro analysis to guarantee the highest standards of material integrity and safety.

Experience the epitome of luxury and precision with KOLEGO's commitment to superior craftsmanship and exceptional quality.

Sand Core Making Workshop

We operate a sophisticated facility and full production lines with 8 state-of-the-art sand core-making machines, allowing us to efficiently produce up to 11,500 high-quality faucet body cores per day. Our advanced manufacturing capabilities ensure precision and consistency in every component, meeting the highest standards of craftsmanship and reliability.

Casting Workshop

Our casting processes are meticulously optimized for precision and efficiency, showcasing our dedication to excellence in environmental responsibility and manufacturing. We operate 2 gravity casting machines and employ a spectroscopy analyzer to guarantee that each faucet body exceeds 59% copper content with less than 2% lead. Before casting, every batch of molten copper undergoes meticulous spectroscopic analysis to meet our high-quality standards. Our dedication to refining our casting process guarantees that our products exceed expectations in both quality and affordability.

CNC Machining Center

At KOLEGO, we understand that meticulous thread processing is essential for high-end faucets. This precision guarantees a flawless aesthetic appeal and exceptional functional reliability. Our commitment ensures smooth assembly, a secure fit, and long-lasting performance, epitomizing the quality expected from premium fixtures.

Our advanced CNC machining centre performs six precise operations, significantly enhancing thread accuracy and aesthetics. With four state-of-the-art peeling machines, we carefully prepare each faucet body, streamlining the polishing process. This advanced technique improves surface quality, boosts polish success rates, and minimizes defects. The result is a collection of faucets that exemplify perfection and reliability, embodying KOLEGO’s legacy of exceptional craftsmanship and timeless quality.

Unassembled Faucets

Polishing Workshop

At KOLEGO, we prioritize both quality and our workers' well-being. With 50 state-of-the-art polishing stations equipped with eco-friendly dust extraction systems, we ensure a clean, dust-free environment for our craftsmen and products. This dedication not only enhances their work experience but also contributes to the flawless finish of our high-end faucets and other products.

Electroplating

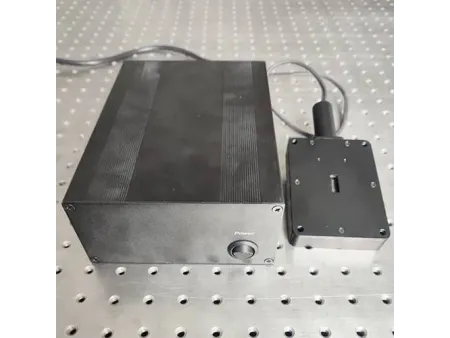

At KOLEGO, precision is paramount. Our advanced facility includes a dedicated electroplating thickness tester, meticulously verifying the base thickness of every electroplated batch to ensure impeccable surface quality. This dedication guarantees our products epitomize durability, reliability, and timeless elegance.

Electroplating Defect Detection

Precision is paramount. Our advanced facility includes a dedicated electroplating thickness tester, meticulously verifying the base thickness of every electroplated batch to ensure impeccable surface quality.

Post-electroplating inspection ensures the integrity of the finish, eliminating issues such as thin layers or micro-perforations. This dedication guarantees our products epitomize durability, reliability, and timeless elegance.

Assembling Workshop

Through meticulous, streamlined assembly of faucet components from semi-finished stages to final pieces, we ensure each piece meets the highest standards of craftsmanship and durability. Our process combines precision engineering with rigorous quality checks at every point of the assembly process, guaranteeing that every faucet, mixer and accessory delivers exceptional performance and aesthetic appeal.

Finished Products Warehouse

Our dual-level warehouse, with a capacity to store up to 50,000 finished faucets, embodies our dedication to excellence and efficiency. Each faucet is meticulously packaged and stacked on plastic pallets, ensuring optimal protection and dryness. This precise organization enhances forklift efficiency, significantly accelerating and streamlining the loading process. Experience unmatched quality and efficiency with our meticulously managed logistics.

Shipping

Our logistics are optimized for maximum efficiency and world-class service. Container trucks load directly at the warehouse entrance, allowing swift and seamless forklift operation. Strategically located along provincial roads, highways, and near the world-renowned Ningbo Port, we ensure expedited and hassle-free shipping. Experience the pinnacle of professional logistics with our expertly managed facilities.