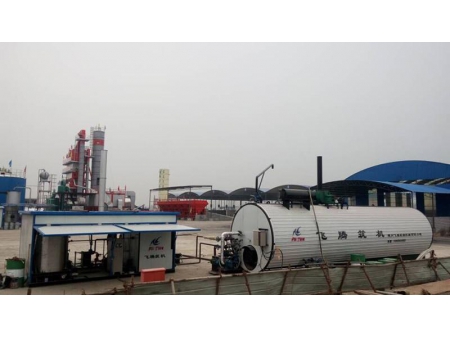

Coal Gas Generator

HONGJI coal gas generator adopts air and water vapor as the gasification agent and is the advanced equipment in producing mixed-gas. It is suitable for gasifying coke and other fuels. Coal gas generator is commonly used in many industrial fields like machinery, metallurgical, chemical, glass, building materials, light industry, food, textile industry.

Features

1. The coal gas generator is designed with small investment in main equipment.

2. It is quick to start and is safe and convenient.

3. Easy operation

4. The generator can save 20% fuel than the direct oil-burning.

5. Compared to direct fuel thermal processing furnace, the use of the hot gas can save over 60% of energy.

6. The coal gas generator is characterized by its significant effect of dust collection, which can protect environment. It is the essential equipment of hot-processing systems.

Export Countries

India, Vietnam, Kazakhstan, Mongolia, Ecuador, Iran, Pakistan, Australia, the Middle East and other countries and areas.

Procedures

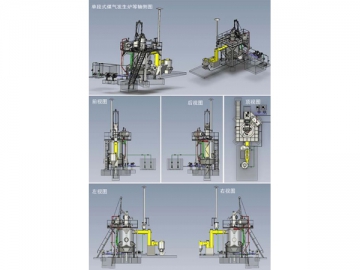

1. The coal gas generator adopts the scientific technology structure to analyze water molecules, which can produce hydrogen (H2) to combust and oxygen (02) for helping combustion. As a result, the temperature will increase rapidly in combustion studio.

2. With this cycle, the fuel will completely burn in the oven and produce great heat value.

3. Coming with the full combustion and swirl cyclone combustion technology used in the combustion chamber, the coal gas generator can achieve high temperatures. Additionally, it can also avoid the emission of harmful gases, such as C0, C02, N0, S02, smoke removal, dust removal, desulfurization to achieve the requirements of environmental protection department.

| Model | | | | | | | | | | | |

| Inside diameter (mm) | 800 | 1000 | 1200 | 1500 | 1600 | 1800 | 2000 | 2400 | 2600 | 3000 | 3200 |

| Active furnace area (m2) | 0.5 | 0.785 | 1.13 | 1.77 | 2.01 | 2.54 | 3.14 | 4.52 | 5.31 | 7.07 | 8.00 |

| Suitable fuel | weak coherent gas carbon,anotherracite,burnt carbon | ||||||||||

| Fuel granularity (mm) | 25-80 | ||||||||||

| Fuel consumption quantity (kg/h) | 40 100 | 70 140 | 120 190 | 160 350 | 350 460 | 500 600 | 500 720 | 700 1040 | 850 1200 | 1700 2000 | 1800 2200 |

| Gasifying agent | Air , steam | ||||||||||

| Gas yield ( m³/h) | 140 350 | 245 490 | 420 670 | 560 1200 | 1200 1600 | 1500 2100 | 1750 2500 | 2500 3600 | 3000 4300 | 6000 7000 | 6500 7500 |

| Gas calorific value (Kj /Nm³ ) | 5020-5670 | 5020-6000 | |||||||||

| Water jacket heating area() | 4.02 | 5.02 | 6.78 | 10.37 | 11.06 | 12.44 | 17.58 | 21.87 | 23.69 | 30.16 | 31 |

| Steam output (kg/h) | 60 | 80 | 130 | 200 | 220 | 260 | 350 | 420 | 600 | 840 | 900 |

| Gas outlet tempe rature () | (400-500)Plants related with the coal | (400-500)Plants related with the coal | |||||||||

| Gas outlet pressure (Pa) | 1000 | 980-1470 | 1470-1960 | 1470-1960 | |||||||

| Gas outlet diameter (mm) | 219 | 325 | 325 | 426 | 426 | 529 | 630 | 720 | 820 | 1020 | 1050 |

| Air pressure (Pa) | 3000 | 4000 | 4000 | ||||||||

| Saturated air temperature | 50-60 | 50-65 | |||||||||

| Ashpan rotated speed (r/h) | 0.177-1.77 | ||||||||||

| Equipment gross weight (t) | 3.5 | 4.5 | 5 | 7.5 | 10 | 20 | 23.4 | 29.8 | 32 | 37.6 | 38 |

| Complete machine power (kw) | 6 | 6 | 6 | 7 | 8 | 10 | 14 | 20 | 20 | 27 | 27 |

| Air inlet diameter (mm) | 108 | 108 | 140 | 165 | 219 | 325 | 325 | 426 | 426 | 426 | 426 |