Downspout Forming Machine

Downspout Forming Machine HS

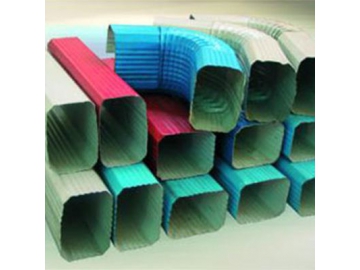

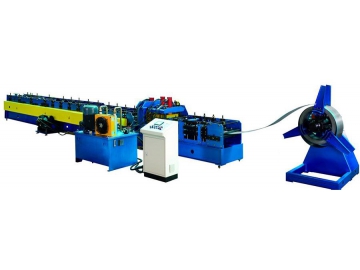

Our downspout forming machine is designed to produce close type downspout after cold forming and auto whipstitching processes. A curving machine can bend the downspout into a downspout elbow of different matching angles. This downspout forming equipment is suitable for downspout bending and necking. Under mechanical control, it is highly automatic, and the bending angle can be manually adjusted. The downspout it produces is widely used in steel structure buildings, villas, and more. We at Jinggong Science & Technology design downspout forming machine in various specifications and models to suit customers' requirement.

Main Components

Jinggong downspout forming machine is mainly made up of a decoiler, sheet guiding equipment, roll forming system, cutting equipment, product supporter, hydraulic system, and control system.

| Item | Parameter | Remark | |

| Suitable material | Type | Color coated steel sheet | |

| Thickness | ≤0.55 mm | According to customer' requirement | |

| Yield strength | ≤350 MPa | Depending on customers' material characteristic | |

| Width | ≤500 mm | According to different profile shape | |

| Coil weight | 3 or 5 T | Optional | |

| Working speed | ≥15 m/min | ||

| Roller material | Hard chromium plated 45 steel | ||

| Driving mode | External chain drive | ||

| Electric control system | Industrial computer PLC frequency control | ||

| Console mode | Touch screen+ button | ||

| Motor power | 10.5 Kw | As per technical requirement | |

| Outline dimensions (LXWXH) | 14X1.2X1.5 m | ||

Jinggong Science & Technology is a China downspout forming machine manufacturer and supplier. We provide a wide range of construction materials machinery, such as sandwich panel machine, roll forming machine, steel tile forming machine, and guardrail forming machine etc. Our products are ISO9000 and CE certified, and are very popular in the USA, Cambodia, Algeria, Lebanon, Malaysia, and more. For more detailed product information, please browse our website or contact us directly.