Crankshaft Machining

Nazhen is the professional crankshaft machining service provider. With over 20 years of experience in manufacturing, Nazhen can provide different kinds of custom crankshafts according to customers’ requirements. We can provide full sets of service of manufacturing from billet crankshaft to finished crankshaft. Usually, there are two kinds of methods of billet crankshaft manufacturing: cast crankshaft and forged crankshaft. The method of billet crankshaft manufacturing is mainly decided according to the crankshaft material selected by our customers. Meanwhile, different kinds of machining craft can be customized.

- Cast crankshaftManufacturing of nodular cast iron crankshaft usually adopts casting because this kind of material features low cost and high cost performance. Nodular cast iron crankshaft has the following performances: wear resistant, impact resistant and stress resistant etc. It can be widely used for equipment sets requiring transmission crankshaft such as air compressor and refrigerating machine.

- Forged crankshaftWhen the crankshaft selected by our customer is made of carbon steel or alloy steel, we usually adopt forging. Thus, this kind of crankshaft can have stronger resistance to impact, tensile force and resistance to stress. It can be widely used on automobile and compressor.

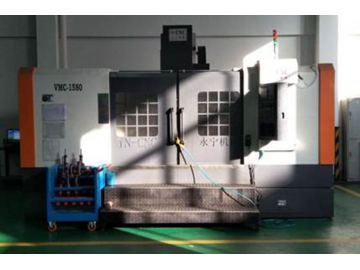

Superior material, precise machining equipment and rich experience should be equipped in order to produce a superior crankshaft. Nazhen has all these features.

The main steps for normal crankshaft machining are listed below: