Mold Manufacturing

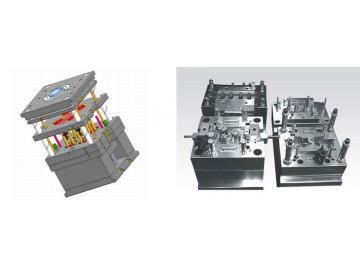

Tenlita Model provides our customers with two types of molds which are injection molds and die casting molds to manufacture plastic products and metal parts.

Application

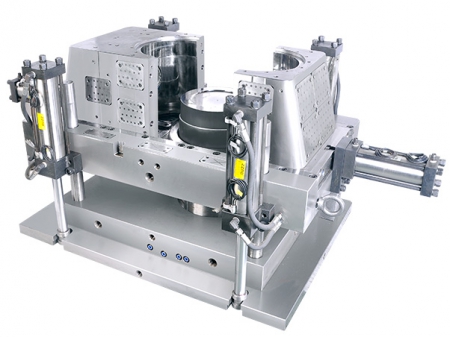

Die casting mold applicable in molding of metal

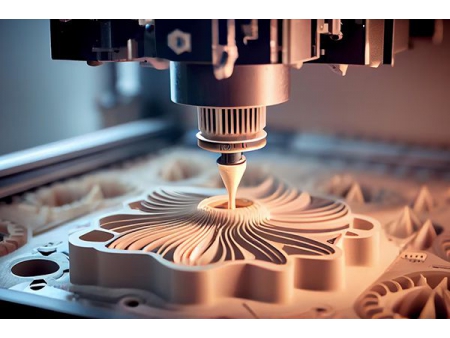

Production process

Metal raw materials are added into the preheating feeding chamber and it is melted under high temperature and high pressure. Next, apply pressure at the pressure column. The metal molten enters the cavity through the casting system of the mold and is gradually hardened. This molding method is called die casting molding and the mold used is called die casting mold.

Materials of the mold

We have 5 mold production lines that can produce a maximum of 300 sets of die cast molds per year. We usually customize the mold materials and accessories according to the customers′ needs, and often use materials such as H13, DIEVAR, 8407, 8418, SKD61, DAC, DH-31, 1.2344 etc.

- Mold for development purpose

Production period 1.5 to 2 weeks

Production quantity range from 20 to 1000 - Small batch production of molds

Production period 2 to 4 weeks

Production quantity range from 200 to 5000 - Medium-scale production of molds

Production period 4 to 5 weeks

Production quantity range from 5000 to 20000