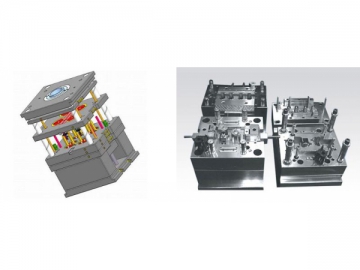

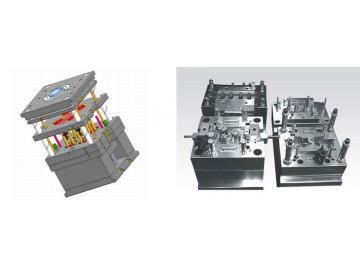

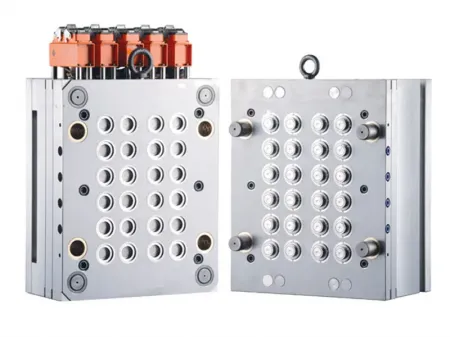

Mold Manufacturing

Borui Model provides our customers with two types of molds which are injection molds and die casting molds to manufacture plastic products and metal parts.

Application

Injection molding is applicable in the molding of thermoplastics

Advantage

Short molding period, high productivity, mild wear on the mold caused by the molten materials, able to conduct large batch production of plastic products which are high precision in size with complicated shape, pattern on the surface, clear marks.

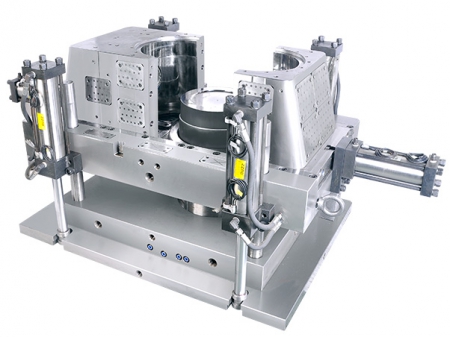

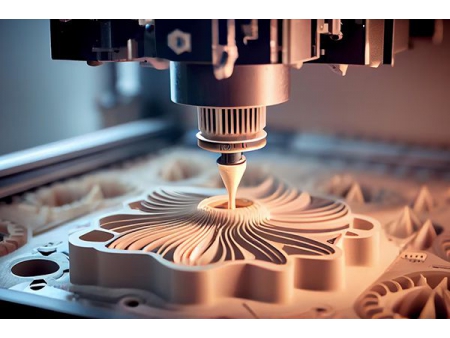

Production process

The plastic is first added to the heating barrel of the injection machine and melted after substantial heating. With the push of the screw or plunger of the injection machine, the plastic molten is injected into the mold cavity via the nozzle and the mold casting system. Later, the formation of injection mold is completed when the melted plastic is hardened into the shape of the mold under the physical and chemical reaction.

Materials of the mold

1. Carbon Steels

2. Cold Work Steels, Hot Work Steels

3. Plastic Mold Steels, H.S Steels

- Mold for development purpose

Production period 1.5 to 2 weeks

Production quantity range from 20 to 1000 - Small batch production of molds

Production period 2 to 4 weeks

Production quantity range from 200 to 5000 - Medium-scale production of molds

Production period 4 to 5 weeks

Production quantity range from 5000 to 20000