Manufacturing Capability

As a professional manufacturer of commercial and household floor mats, we have significant experience in the customization of floor mats with applied logos or patterns for wholesalers and distributors worldwide.

With a factory equipped with 38 pieces of floor mat production equipment and 60 sets of molds, we have everything needed to provide you with fully customized floor mats with a monthly output capacity of 18,000 square meters. We can work with you to produce mats that are suitable for your application by customizing the materials, colors, textures, thickness, dimensions, borders, and backing.

You are more than welcome to visit our factory!

The materials most common in our floor mats include PVC, EVA, aluminum alloy, rubber, nylon, polypropylene, polyester, and cotton. Incoming raw materials are strictly tested for properties like their hardness, temperature resistance, odor, and stable mold release. Only qualified materials are allowed to be put into production.

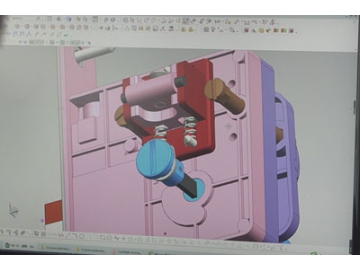

- Injection molding:

mainly used for the production of modular floor mats.  Flocking:

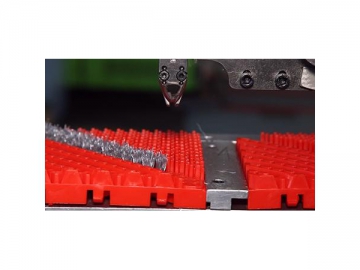

Flocking:

8 sets of rapid flocking equipment are responsible for the flocking of the brush mats, which will exclude the un-flocked and unqualified mats. Automatic engraving machine:

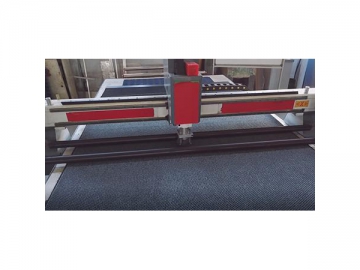

Automatic engraving machine:

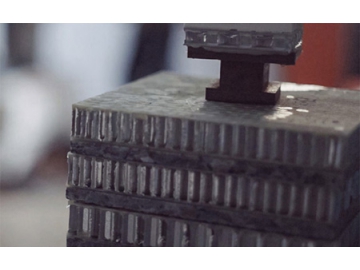

used for engraving logos and cutting the carpet. Embossing machine:

Embossing machine:

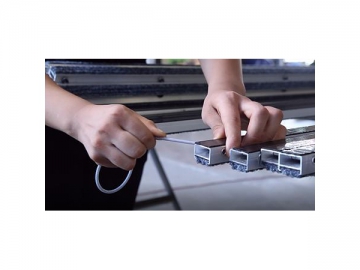

applied to the embossing of logos and the pressing of edgings of specially customized modular mats. Perforation of an aluminum floor mat.

Perforation of an aluminum floor mat.

-

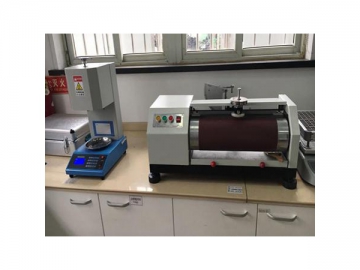

High and low temperature universal testing machine:

adopted to test the finished products to achieve the industrial standard resistance to high temperature.

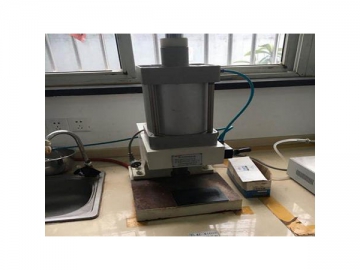

Hardness testing machine:

Hardness testing machine:

used to test the hardness of raw materials, so that raw materials with appropriate hardness can be selected according to different products or customer requirements.