Fence Manufacturing

Since 1992, we have been honing our craft as a manufacturer specializing in fence products. We employ a complete manufacturing process to create high-quality fence products according to customer requests.

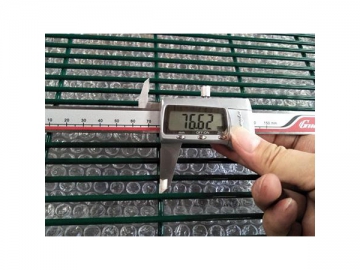

BiaoSheng is equipped with a complete range of processing equipment for wire drawing, straightening, and cutting to process low carbon steel wire and other raw materials into wires of specific diameters. The machines can automatically adjust a suitable length of wires and then cut them off. After surface treatment, the wires will be perfectly smooth. This ensures long-term performance and a clean appearance.

BiaoSheng welds the wires and pipes into wire mesh and column according to customer requirements. The surface of the products is smooth, and the area around the welding point is flat and aesthetically pleasing.

The welded wire mesh is submerged in a bath of molten zinc to apply a zinc coating. This gives the wire meshes good corrosion resistance. Before galvanizing, we perform pickling on the mesh first, ensuring its surface will be smooth and free of impurities.

The wire mesh is put into diluted solution of phosphoric acid and phosphate salts to apply an insoluble conversion coating. It serves as a surface preparation for further powder coating and dip coating, making the surface smoother and flatter.

Biaosheng uses powder supplied by Akzo Nobel and Dupont. We use an electrostatic gun to spray the powder coating onto the surface of the wire panel and column. After being exposed to elevated temperatures to finish the curing process, the wire panel and column will be smooth. During this process we are able to complete spraying with different colors according to your requests.

After being heated, the plastic powder or dip coating liquor will attach to the mold. Then, it will be cooled down and cured. A plastic film on the wire panel surface can protect and make the products more resistant to corrosion and rust.

Usually, BiaoSheng will strict test the first finished good. After it is qualified, we will carry out mass production to provide high-quality products.

BiaoSheng uses metal pallets, wood planks, stretch wraps and other materials to package finished goods, which can prevent the products from being damaged during transportation.