Installation and Commissioning

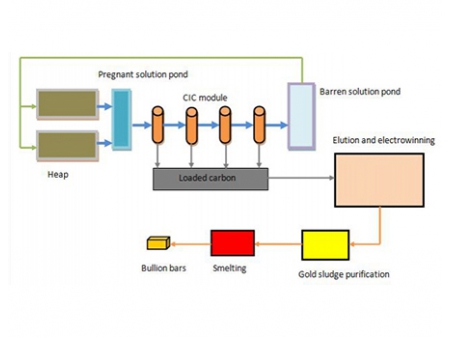

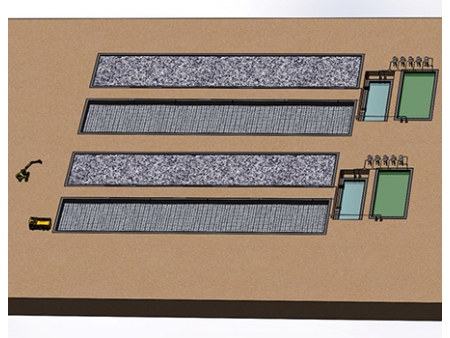

HZE's modular designs for mineral processing projects enable efficient system installation; with strict schedules, operating procedures and inspection standards, time and costs are greatly reduced.

Owners may choose to assemble their own teams to set up and troubleshoot after obtaining their full sets of equipment. HZE can also send out technicians to the site to offer technical instruction, inspect the project's quality and help the site manager in managing.

Since all machinery and main parts are manufactured in-house and shipped in containers, the on-site assembly process is generally non-complex with the exception of welding on larger tanks. This is cost-effective and helps save time.

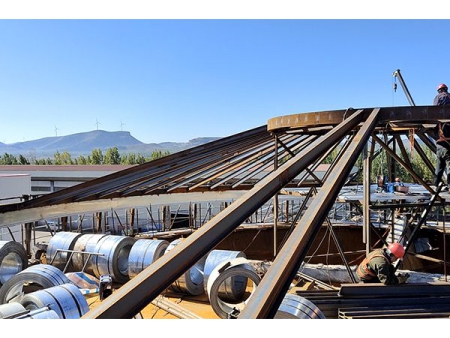

- Installation of main equipment

Large-scale construction production

Large-scale construction production Platform installation

Platform installation Installation of auxiliary facilities

Installation of auxiliary facilities Installation of electrical equipment

Installation of electrical equipment Installation of pipeline instrument

Installation of pipeline instrument Field painting

Field painting

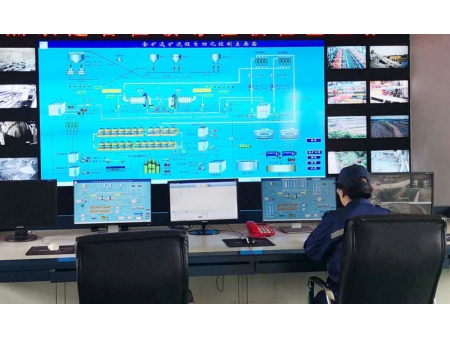

HZE will follow the design documents and the customer's situation to create detailed commissioning procedures and requirements. We will also make certain adjustments and tests to the facilities, processes and equipment of the concentrator to ensure its proper operation.

Once the assembly is finished, we will check the results with the management of the customer, and provide comprehensive training for the plant personnel prior to handing the plant over.

No-load test run of single equipment → No-load linkage test run → Test run of water supply system → Test run of air supply system → Test drive of heating and ventilation system → Single unit test run with water → Linkage test run with water → Instrument test → Feeding linkage test run → Automation system commissioning → Production index commissioning.