Gold & Silver Vat Leach and CIC

If the gold content of the ore or tailings is of lower grade but still easy to process, the vat leaching and CIC is an ideal beneficiation process. Not only will it reduce the financial investment in the plant, but you will quickly see a return on this investment.

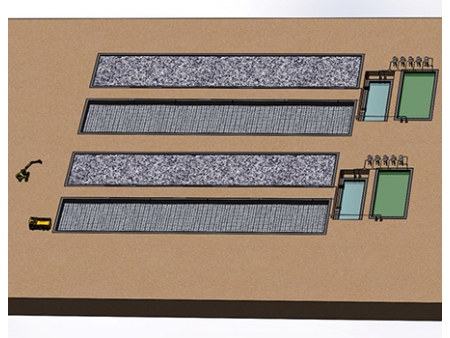

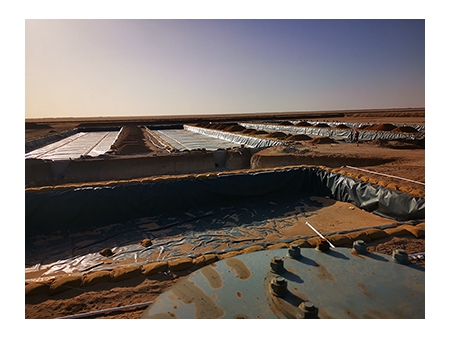

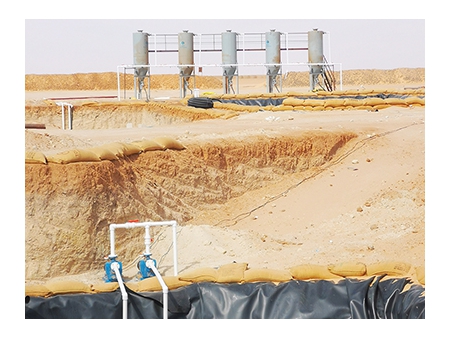

Crushed ore or tailings with a certain size are put into a leach pad lined with a anti-seepage geomembrane. If the clay content of the ore is too high or the water permeability is inadequate, it may need to be granulated or mixed with cement to enhance permeability. The pregnant solution created by leaching will pass through a filter layer on the bottom and collect in a pregnant solution pond, then flow into a CIC module composed of multiple activated carbon adsorption columns.

Gold from the pregnant solution is absorbed, and the solution is transformed into barren solution and recycling back into the pond. The loaded carbon is either burned or sent to an desoption-electrowinning system to recover the gold.

HZE has designed a vat leaching system with a unique aeration approach and distinguished liquid collection pipeline, resulting in a decrease in cycle time and an increase in recovery rate of at least 5%.

We offer a variety of vat leaching-carbon adsorption system specifications. Our services include sending technicians to guide leaching construction, loading, commissioning and trial production onsite, followed by unloading and subsequent process treatment. We also provide comprehensive operation training and guarantee our services.