Custom Medical Oxygen Generation System

Request a Quote

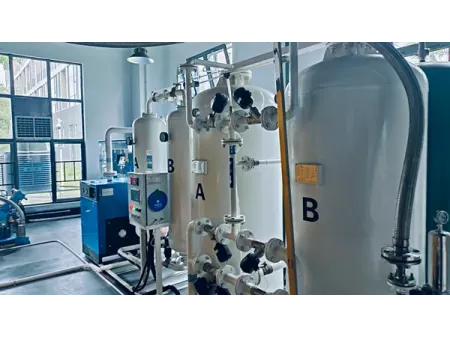

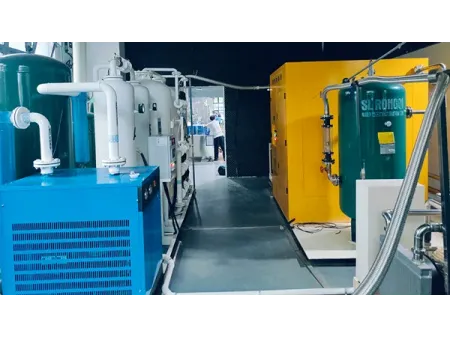

Custom-Built PSA Oxygen Generator (with Oxygen Filling Station)

The medical oxygen on-site filling station produces medical-grade oxygen through pressure swing adsorption (PSA) technology and supports immediate oxygen supply at the point of use. Oxygen is physically separated and purified from ambient air to meet clinical requirements for on-site generation, storage, and filling.

Technical Specifications

- Oxygen capacity: 1-200Nm³/h (standard conditions)

- Oxygen purity: 93%±2% (per Chinese National Standard)

- Outlet pressure: 0.1-0.55MPa (gauge, adjustable)

- Oxygen dew point: ≤-40°C (at atmospheric pressure)

Process Description

- Feed Air Pretreatment

Clean compressed air is filtered and dried to remove moisture, oil mist, and particulate impurities, ensuring stable and clean inlet conditions. - PSA Adsorption & Separation

Zeolite molecular sieve selectively adsorbs nitrogen under controlled pressure, allowing oxygen to accumulate in the gas phase.

Dual-tower PSA operation supports continuous oxygen production. - Continuous Production & Purification

Two adsorption towers operate alternately. One tower performs adsorption and oxygen production, while the other undergoes depressurization and regeneration. This ensures an uninterrupted supply, with oxygen purity stable at 93%±2%, or upgradable to 99.5% based on specific clinical or industrial requirements. - Storage, Delivery & Commercial Filling

Medical-grade oxygen is buffered in storage tanks and delivered through pipelines or filling equipment to clinical terminals, supporting immediate oxygen supply and cylinder filling. - On-site filling reduces supply chain dependency and operating cost

In regions where medical oxygen cylinders are expensive or difficult to transport, on-site filling stations provide a practical solution. Medical oxygen generators support local oxygen consumption, while surplus oxygen is filled into cylinders for distribution or sale, improving supply reliability and creating additional revenue opportunities.

Technical Parameters

| Model | Flow rate (Nm³/h) | Equivalent hospital beds | Power(kW) | Dimensions (L×W×H, mm) |

| 1 | 20 | 5.8 | 1800×1400×1800 | |

| 3 | 50 | 7.6 | 2000×1400×1900 | |

| 5 | 100 | 7.8 | 2000×1500×1900 | |

| 10 | 150 | 16.7 | 2000×1500×2100 | |

| 15 | 300 | 19.9 | 2500×1800×2350 | |

| 20 | 400 | 33.5 | 2500×1800×2350 | |

| 30 | 600 | 38.9 | 2800×2000×2350 | |

| 40 | 800 | 47.9 | 3000×2000×2450 | |

| 50 | 1000 | 58.5 | 3800×2200×2750 | |

| 60 | 1200 | 78.8 | 3800×2200×2850 | |

| 70 | 1500 | 98 | 4500×2300×3100 | |

| 80 | 1800 | 98 | 4500×2300×3100 |