Air Compressor for Metalworking

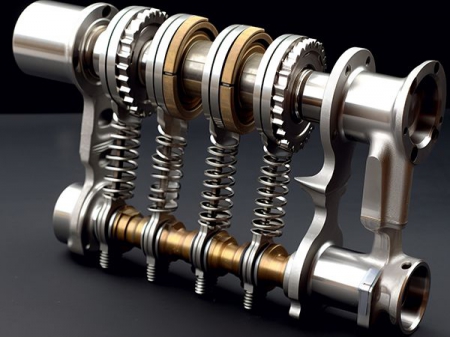

At the heart of metal manufacturing lie pneumatic tools, which are devices powered by compressed air (such as drills, polishers, and rivet guns). The essence of these tools is the compressed air, and HAREYES air compressors stand as a vital source, propelling these instruments to operate at high performance.

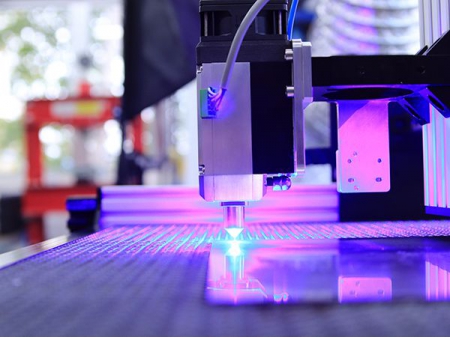

In the intricate process of metalworking, spraying is a common application. To coat steel surfaces uniformly, compressed air plays an important role in spraying paint with precision. With HAREYES, you get compressed air at the ideal pressure, ensuring quality and consistency in every spray.

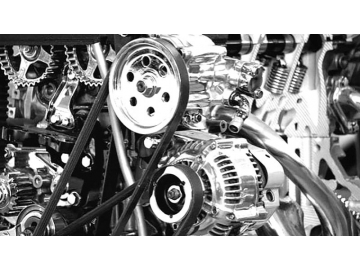

In metal manufacturing, several pieces of equipment rely on compressed air, which requires regular monitoring of air flow and pressure. HAREYES air compressors stand guard, delivering the needed compressed air, ensuring no anomaly goes undetected.

- Which pneumatic tools can your air compressor support?

From drills to polishers and rivet guns, HAREYES supports a wide array. - What types of spraying can your air compressor be used for?

HAREYES is versatile for all sprays, including paint, glue, varnish, and more. - Which devices can use the compressed air from your compressor?

Any equipment needing compressed air can find an ideal solution in our products. - What makes air compressors important in metal manufacturing?

In the metalworking industry, air compressors are linchpins. Providing the much-needed pneumatic power for tools, spray equipment, and an array of devices requiring compressed gas, these industrial assets dictate the quality and efficiency of your operations. HAREYES industrial air compressors stand as a robust solution for this demanding field, offering both stability and safety in air supply.

Our experts are happy to answer all your questions and concerns as well as sales and after-sales service.