Non Ferrous Metal Welding

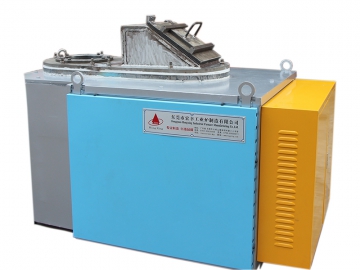

The power assisted steering pipeline and supports are the most important parts in an automobile brake system. Although arc welding is often used, it is difficult and inefficient to operate, and it has a high defective rate, meaning it cannot always meet the requirements of the design. Depending on the pipeline structure and working conditions, gas flame welding is often the best welding method. Our oxy-hydrogen gas welding equipment has the following advantages:

1) Dissimilar metals may be welded together and there are no rigid limitations on the different thickness of workpieces.

2) Available to weld multiple workpieces efficiently.

3) Small heat affected zone and intensive oxy-hydrogen flame ensures high precision welding.

4) Smooth and beautiful welding. Since there are no beginning compositions generated in oxy-hydrogen combustion, no dirt or black marks are left on the workpiece, saving you time on secondary cleaning and polishing.

5) Simple equipment and low investment, saving you 50% in expenses than if you used acetylene.

6) No environmental pollutants.

2. Welding household air-conditioner and refrigerator parts

The cooling system of household appliances such as air-conditioners and refrigerators are usually made of steel, aluminum or other non-ferrous metals. The whole system is composed of a fully closed pipeline. Such strict requirements rely on an excellent welding process to ensure good quality. Brazing welding and gas welding are mostly used for pipe connections.

The quality of the welding will affect not just the pipe connection but the whole machine's performance. Recently produced air-conditioners and refrigerators mostly use oxygen-acetylene as the heat source for braze welding, but this takes a lot of energy and pollutes the environment, so more and more manufacturers are switching to oxy-hydrogen welding for steel and aluminum household appliances to save energy and protect the environment.

3. Welding transformer wiring terminals, motor enamelled wire, and lead-acid battery plate in the electronic industry

Welding technique also plays an important role in magnetic wire and storage battery products which require highly precise workmanship. The welding performance has a direct impact on product quality, liability, service life, and production cost. The welding of enamelled and other magnetic wires is often done by soft soldering which may still create defective or sealed off joints or spots that peel off when under heat.

Other welders use electric processing, but this is an inconvenient way to weld multi-strands of material together. And while oxygen-acetylene and propane have the advantages of speed and simplicity, they also use up a lot of energy and may release pollutants. More and more, oxy-hydrogen is being used to replace traditional fuels in the electronic industry.

Our oxy-hydrogen machine can be used in various flame processes, such as the welding of metal wires, IC encapsulation, thermoelectric couple wires, LED wafer integration, hinges on the metal frames of glasses, cutting and fusing for fine components, sand hole fusion repair for tooth models, small castings, quenching and softening of small accessories, and so on.

Recommended Products