Pneumohydraulic Drives

Request a Quote

The pneumohydraulic drive functions as a fully integrated drive system. Its modular configurations and specialized accessories ensure seamless adaptation to a wide range of application scenarios. Custom-engineered designs such as configurations optimized for welding enable these cylinders to deliver high precision and reliability, meeting the diverse demands of customers.

Cylinder Structure and Features

- High-precision guide bushing and locating pilots

- Dual-supported high-strength steel working piston rod

- Sealing elements with patented seal grooves for long-term lubrication retention and extended service life

- End-of-stroke cushioning pad that reduces return stroke noise

- Dual-plunger oil cylinder sealing system for complete separation of air and oil with venting

- Integrated internal air circuit design

- Bypass release with integrated overflow buffering

- Oil reservoir exhaust port

- Standardized pneumatic interfaces

- Force-stroke velocity regulating valve (Type X)

- Integrated test interface

- Integrated pneumatic circuit

- Pressurized sealed oil reservoir

- Double-ended supported spring (or gas spring)

- Boost piston cushioning pad

- Integrated pneumohydraulic intensification control valve

Advantages of Pneumohydraulic Drive

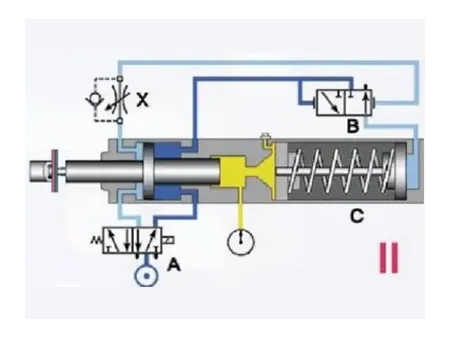

- Initial state: Supports 360° installation at any angle.

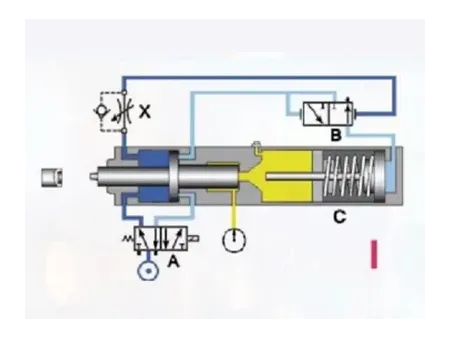

- Fast approach stroke: Driven by the approach cylinder to bring the tool into contact with the workpiece.

- Power stroke: Driven by the rear intensifier to complete pressing or forming operations.

- Fast return stroke: Pneumatic retraction of the approach cylinder and spring-assisted reset of the intensifier.

Typical Industrial Applications

- Automatic press-riveting equipment

- Automated production lines

- Automated production lines

- Automated production lines