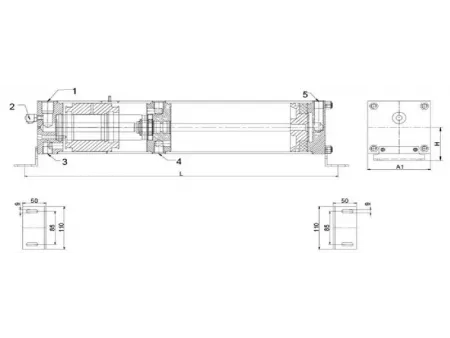

Pneumohydraulic Intensifier, TMPS Series

Request a Quote

- Pressing force 2-2000kN

- Force stroke 6-52mm

- Total stroke 100/200mm

The TMPS series pneumohydraulic intensifier is a high-pressure output device that integrates pneumatic and hydraulic technologies. By utilizing compressed air to drive piston motion and applying Pascal’s Law, it converts input air pressure into hydraulic pressure dozens of times higher. Its core components include the cylinder, oil cylinder, and air-oil conversion barrel, supporting 360-degree mounting without the need for an additional hydraulic unit.

Operating Parameters

| Model | Approach Stroke Force (kg, at 6 bar air pressure) | Return Stroke Force (kg, at 6 bar air pressure) | High-pressure output at A1 under intensification (CC) | H | B | L1 | L, Pneumatic Interface | Hydraulic Interface | ||

| | 400 | 803 | 36 | 137 | 98.5 | 632 | 688 | G1/2 | G3/4 | |

| | 400 | 1462 | 72 | 177 | 118.5 | 692 | 646 | G1/2 | G3/4 | |

| | 400 | 2360 | 137 | 216 | 138 | 771 | 827 | G3/4 | G3/4 | |

| | 400 | 4795 | 300 | 268 | 159 | 1027 | 1083 | G1 | G1 | |

- High-pressure hydraulic port

- Pressure test port

- Fast advance port

- Boost return port

- Boost port