261 Non Sparking Phillips Screwdriver

The 261 non sparking Phillips screwdriver is a specialized tool used for hazardous applications that require the tool to be spark-free and corrosion-resistant. This type of tool is designed for loosening or tightening the Phillips head screw. It is advantageous over conventional screwdrivers because it does not generate sparks from impact, friction, strike or collision, which might incur a risk of fire and explosion.

To achieve the feature of spark-resistance, we select aluminum bronze or beryllium copper to build the tool as both materials are spark-free. In addition to the spark-proof feature, beryllium copper is also anti-magnetic. After heat treatment, beryllium copper can achieve a hardness of HRC35 while the aluminum bronze can reach a level of HRC25. Drop-forging process gives the tool high tensile strength, long service life and stable mechanical performance. All these processing techniques are of advanced level in the screwdriver manufacturing industry.

Features

1. The company conforms to ISO8764 standard.

2. Our Phillips screwdriver is designed for fitting into Phillips head bolts.

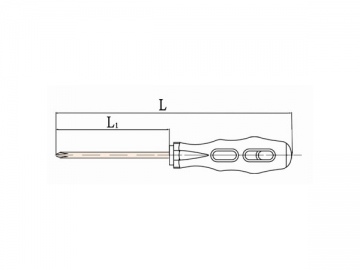

| Model | L1 inch | size | L1 mm | L mm | Φ mm | Be-Cu g | Al-Cu g |

| 261-1002 | 2 | 0 | 50 | 134 | 3 | 35 | 32 |

| 261-1004 | 3 | 1 | 75 | 159 | 4 | 70 | 63 |

| 261-1006 | 4 | 1 | 100 | 205 | 5 | 75 | 70 |

| 261-1008 | 5 | 2 | 125 | 240 | 6 | 100 | 95 |

| 261-1010 | 6 | 2 | 150 | 265 | 6 | 110 | 105 |

| 261-1012 | 8 | 3 | 200 | 327 | 8 | 165 | 155 |

| 261-1014 | 10 | 3 | 250 | 377 | 8 | 185 | 170 |

| 261-1016 | 12 | 4 | 300 | 427 | 9 | 245 | 230 |

| 261-1018 | 14 | 4 | 350 | 477 | 9 | 270 | 255 |

| 261-1020 | 16 | 4 | 400 | 550 | 9 | 295 | 280 |

| 261-1022 | 18 | 4 | 450 | 600 | 9 | 320 | 300 |

Different models offer choices of specifications. In addition to the above models, we also can custom make the product according to customer specific requirements or based on the technical drawings.

Related Names

Sparkless Phillips Drive Tool Saler | Device to Avoid Mining Accident | Specialized Hand Tool