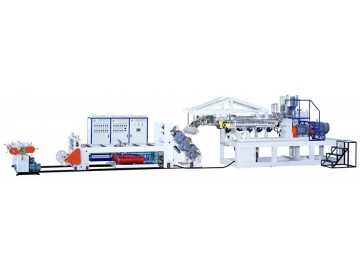

Three-layer Cross-linked Cable Extrusion Line

Application

This three-layer cross-linked cable extrusion line is nitrogen & water cooling cross-linked cable production line. It is suitable for manufacturing 6 KV to 35 KV cross-linked polyethylene insulated cable.

Product Features

Advanced design and diversified production modes guarantee the high quality finished cables.

Advantages

The extrusion machine requires low investment but offers high efficiency. It is the optimal extruding machinery for high-voltage cable producing.

Update and Improvement

1. The three-layer cross-linked cable extrusion machine can choose mold and die sleeve, so that it can produce cables of different specifications without stopping.

2. Standard or high speed wire can be configured to the extruder for different application requirement.

3. Threes sets of extruding machines apply the sleeve welded copper tube rather than the spinal copper tube for cooling.

4. Cooling system of the extruding equipment uses the ferrule fitting connection. This type of connection is easy and convenient to install.

5. To improve the dielectric strength and quality of the cables, the three-layer cross-linked cable extrusion line uses nitrogen cooling system rather than the water cooling system.

| Voltage Grade | 6 ~ 35KV | |

| Product Specification | Press Copper Core: 25~630mm2 Aluminum core: 35~800mm2 | |

| Max. Cable Weight | 7.6 kg/m | |

| Maximum Diameter of Cable | Ф70 mm | |

| Cable Structure (Thickness) | Conductor Screen | 0.5 ~ 2mm |

| Insulation | 3.4 ~ 10.5mm | |

| Insulation Shielding | 0.5 ~ 2.0mm | |

| Materials | Conductor | Pressed copper, pressed aluminum wire |

| Conductor Screen | Shielding materials for crosslinking conductor | |

| Insulation Shielding | Crosslinked Polyethylene | |

| Maximum Line Velocity | 30m/min | |

| Tube Distribution | Semi-suspension chain type | |

| Inclination Angle of Cooling Section | 1° ~ 2° | |

| Coefficient of Catenary Suspension | 200 ~ 150 | |

| Length of Cross-linked Section | About 40.89m | |

| Length of Pre-cooling Section | 12m | |

| Length of Cooling Section | 50~65m | |

| Design Pressure | 1.6Mpa | |

| Rail Traversing Type Pay Off (Strengthened) | 2 sets |

| Wire Clamping Device | 1 set |

| Horizontal Accumulator | 1 set |

| Upper Caterpillar (Taping type) | 1 set |

| Ф65/20D Extruder | 1 set |

| Ф90/20D Extruder | 1 set |

| Ф150/25D Extruder | 1 set |

| Crosshead and Guide Tube for Extruder | 1 set |

| Upper Obturator | 1 set |

| Cooling Troughs | 1 set |

| Suspension Type Controller | 1 set |

| Lower Obturator | 1 set |

| Lower Caterpillar | 1 set |

| Meter Printer | 1 set |

| Rail Traversing Type Take Up (Strengthened) | 2 sets |

| Nitrogen Supply or Discharging Device | 1 set |

| Oil and Water Cooling Circulation System | 1 set |

| Electrical Control System | 1 set |

| TV Monitoring System | 1 set |