Aluminum Cladding Extrusion Machine

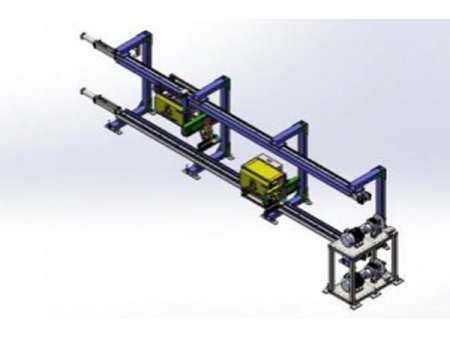

Application

The aluminum cladding extrusion machine is mainly used to extrude the Φ9.5mm or Φ12.0mm aluminum rod into the aluminum tube of below Φ170mm, and then clad the cables. The aluminum tube after processed by a corrugating device serves as the cable protective cover.

Features

1. This aluminum cladding extrusion machine uses the large seamless aluminum tube to clad and extrude the cables. The tube diameter is from Φ60 to Φ160mm.

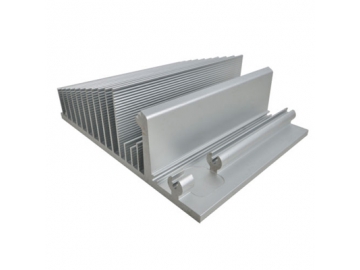

2. It applies the double-wheel, double-groove structure.

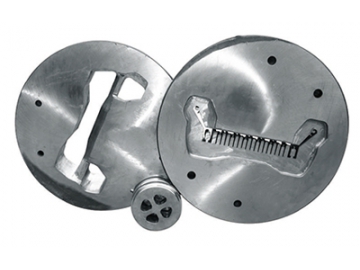

3. The aluminum extrusion machinery adopts the split-type extrusion die, die holder with four symmetrical holes of materials feeding, and dedicated installation tools.

a. The extrusion die holder has four symmetrical holes used for materials feeding. The specially designed holes are beneficial for the uniform molten aluminum flow. Consequently, the optimal cladding effect is ensured.

b. The dedicated installation tools are designed for the split type die which requires high installation precision.

4. This aluminum cladding extruder utilizes the main shaft with water cooling circulating system.