Project Management

Project Start-Up

Listed below are four aspects involved in the initial phase of any stamping die project.

1. Listen to customers and understand their technical requirements.

2. Confirm product specifications

3. Create a project schedule

4. Assess project risks

Huanghe's business department is ready and willing to discuss customer's stamping die projects. After customer approval, we will assign specialized personnel to the project, asking them to create a project schedule, pinpoint critical points in the project and figure out what customer's quality requirements and design standards are.

We use a unified management system to maintain control over each component's finite element models and design documents that will be used in the auto die design. Meetings will be held to assess the potential risks that may affect the project, and take steps to ensure those risks don't happen. When incidents do occur, we work to ensure we can provide solutions.

Project schedules for both internal use and customer reference will be made and sent to the general manager for approval. The project charter and project list will also be written. Other tasks that falls under the personnel's responsibility include organizing project start meetings, announcing the project schedule, and send out project -related documents.

Project Schedule

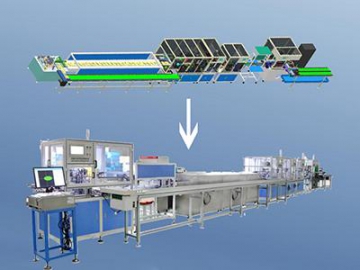

The main activities in this stage include drafting tool and die production plans, analyzing resources on hand, determining the quality standards, and control the production cost.

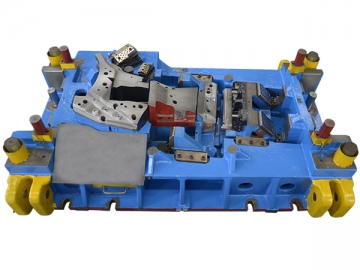

The project manager undertakes control of the stamping die production progress. They check the infinite elements models and design standards used in stamping die designs, and maintain the overall control of design details such as the symbol for bolts, and the location of the car model symbols on the design paper. The manager works together with the die engineers to visit customer sites to sign a Die Design and Construction Agreement with them. During the visit, customers can get answers to questions concerning the project progress, die structure, and possible problems they may run into during daily use.

Project Execution

A temporary project management team will be formed before production actually begins. Specific production processes for key components are strictly controlled to ensure the quality. Die testing is also monitored in real time. A plan is put into place to check that all project objectives have been fulfilled by the end of the day.

The management team also keeps close track of follow-up production processes, including the manufacturing of standard die components, as well as keeping the product assembly progress on schedule. Management staff will visit the production site, and remind the benching personnel of special die structures and project requirements. Any problems found in the design drawing will be corrected immediately by relevant designers. The project management goal is simple: maintain overall control of the project quality.

Project Inspection

The purpose of the project inspection is broken into 3 components:

1. Keep the project on schedule

2. Manage abnormal situations

3. Control project changes

Project inspectors will hold meetings to discuss any problems that arise during inspection. Once defects are found in any of the components, project inspectors should organize technicians and benching personnel to correct them. After reworking, the inspectors will determine if the correction was effective. In the middle of the die testing, inspectors are responsible for sending feedback to the designers and workers on the new component used in the die construction. If necessary, the project schedule will be adjusted. Toward the end of the inspection stage, technicians will go to the customer's location and assist them in finding any other die problems and tighten up the tolerance on any components. When quality problems arise, we will inform our staff to make the corresponding die changes. Documents of the inspection process will be gathered and classified.

Project Summary

This is the final stage of any project. A project summary meeting will be held and a project database will be compiled. It is during this stage that production costs are totaled and a follow-up visit is carried out.

After on-time finish, the designers and technicians will get together to discuss problems and technical challenges that arise from the tooling project, in order to better handle them the next time they arise. All project related documents will be collected and analyzed, and a follow up visit will be carried out to ensure customers are happy with their product.