Custom Industrial Oxygen Generation System

Request a Quote

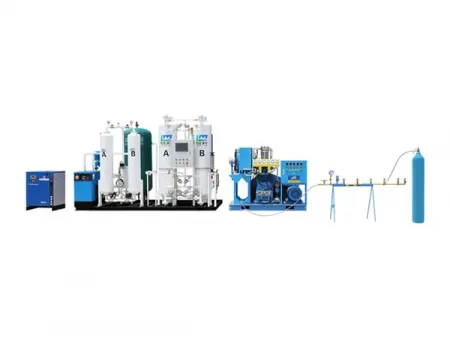

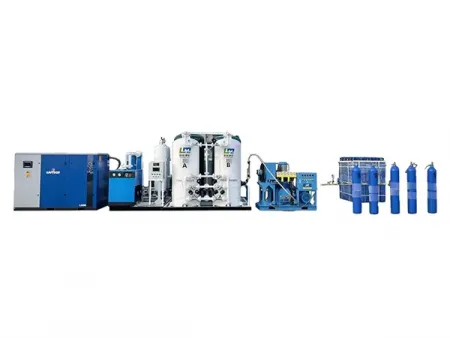

Custom-Built PSA Oxygen Generator with Oxygen Filling Station

For regions or countries where local oxygen cylinder supply is inaccessible and transportation costs are high, LuoMing provides an on-site oxygen cylinder filling station with strong adaptability. Paired with oxygen generators, this oxygen filling station satisfies on-site industrial, medical, or residential oxygen demand while enabling excess capacity to be filled into cylinders for storage and external retail distribution. This approach reduces dependence on traditional oxygen supply logistics and improves resource utilization efficiency, delivering an economical and sustainable on-site oxygen supply and revenue generating solution.

Key Features

- High-purity oxygen suitable for cylinder filling

Standard filling purity reaches 93%±2% in compliance with national standards. Upgraded configurations achieve 99.5% high-purity oxygen. Secondary PSA purification combined with medical-grade filtration ensures oxygen free of contaminants. Oxygen dew point at ≤-40°C, reducing moisture-related internal corrosion. - Efficient and intelligent bottling

PLC-based control enables one-touch operation and unattended operation. Filling purity, pressure, and flow rate are monitored in real time. Qualified oxygen output is available within 30 minutes. Filling pressure ranges from 15-20MPa and supports customized pressure settings to match different cylinder specifications. - Wide application coverage refilling

Skid-mounted design occupies limited space and suits indoor, outdoor, and plateau filling sites. Selected models support mobility for temporary filling and emergency response. Inlet and outlet nominal diameters from DN15 to DN100 ensure compatibility with oxygen generators of various capacities and batch cylinder filling operations. - Safe and reliable charging

Integrated audible and visual alarms combined with automatic overpressure relief mitigate filling risks. Core components feature temperature and corrosion resistance, supporting stable operation and reduced energy consumption compared with conventional filling equipment. CE and ISO compliance supports long-term operational safety.

Standard Configuration (Main Components)

- Air Compressor

- Oxygen Generator

- Oxygen Filling Station

- Oxygen Cylinders

Technical Parameters

| Model | Oxygen purity | Flow rate (Nm³/h, standard conditions) | Inlet nominal diameter | Outlet nominal diameter | Filling pressure (MPa) |

| 93%±2% | 3 | DN15 | DN15 | 15-20 | |

| 93%±2% | 5 | DN15 | DN15 | 15-20 | |

| 93%±2% | 10 | DN25 | DN25 | 15-20 | |

| 93%±2% | 15 | DN40 | DN25 | 15-20 | |

| 93%±2% | 20 | DN40 | DN25 | 15-20 | |

| 93%±2% | 25 | DN40 | DN25 | 15-20 | |

| 93%±2% | 30 | DN40 | DN25 | 15-20 | |

| 93%±2% | 40 | DN50 | DN40 | 15-20 | |

| 93%±2% | 50 | DN50 | DN40 | 15-20 | |

| 93%±2% | 60 | DN50 | DN40 | 15-20 | |

| 93%±2% | 70 | DN65 | DN40 | 15-20 | |

| 93%±2% | 80 | DN65 | DN40 | 15-20 | |

| 93%±2% | 90 | DN65 | DN40 | 15-20 | |

| 93%±2% | 100 | DN65 | DN50 | 15-20 | |

| 93%±2% | 110 | DN65 | DN50 | 15-20 | |

| 93%±2% | 120 | DN80 | DN50 | 15-20 | |

| 93%±2% | 130 | DN80 | DN50 | 15-20 | |

| 93%±2% | 140 | DN80 | DN50 | 15-20 | |

| 93%±2% | 150 | DN100 | DN50 | 15-20 | |

| 93%±2% | 160 | DN100 | DN50 | 15-20 | |

| 93%±2% | 170 | DN100 | DN50 | 15-20 | |

| 93%±2% | 180 | DN100 | DN65 | 15-20 | |

| 93%±2% | 190 | DN100 | DN65 | 15-20 | |

| 93%±2% | 200 | DN100 | DN65 | 15-20 |