DPH190D/220D Triple-Servo Alu-PVC & Alu-Alu Blister Packaging Machine

Pharmaceutical Packaging Machinery Since 1998

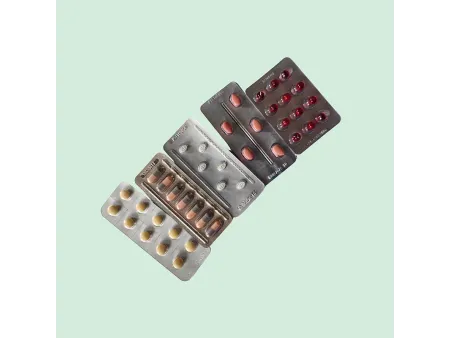

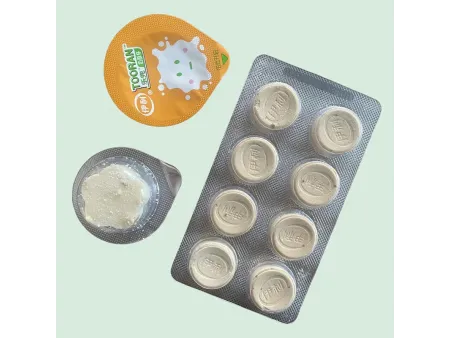

Alu-PVC & Alu-Alu blister packaging machine is driven by servo motors, with a cutting frequency of 20 to 200 cuts/min for Alu-PVC and 20 to 160 cuts/min for Alu-Alu. It is suitable for packaging solid dosage forms of various shapes and sizes, including tablets, capsules, soft gel capsules, and irregular shaped products. It supports multiple materials, including Alu-PVC, PVDC, Alu-Alu, and PET. The machine body is fully covered with stainless steel and fully enclosed, ensuring packaging compliance and product safety.

The equipment meets GMP requirements and represents a stable and economical packaging solution. Visual inspection uses internationally recognized brands, providing high detection accuracy and effectively preventing missing or empty units.

| Model | ||

|---|---|---|

| Cutting efficiency | Alu-PVC: 20–200 cuts/min Alu-Alu: 20–160 cuts/min | Alu-PVC: 20–200 cuts/min Alu-Alu: 20–160 cuts/min |

| Max. forming area | 190 × 200 mm | 220 × 200 mm |

| PVC film | 190 × 0.15–0.45 mm | 220 × 0.15–0.45 mm |

| PTP film | 190 × 0.02–0.03 mm | 220 × 0.02–0.03 mm |

| Power supply | 380 V, 50 Hz | 380 V, 50 Hz |

| Total power | 12.75 kW | 12.75 kW |

| Dimensions (L*W*H) | 4470 × 1000 × 1700 mm | 4470 × 1000 × 1700 mm |

| Weight | 2500 kg | 2500 kg |

| Forming method | Alu-PVC: Pressure molding Alu-Alu: Stamping | Alu-PVC: Pressure molding Alu-Alu: Stamping |

| Sealing method | Roller sealing | Roller sealing |

| Noise level | 75 dB(A) | 75 dB(A) |

| Max. forming depth | Alu-PVC: 18 mm Alu-Alu: 12 mm | Alu-PVC: 18 mm Alu-Alu: 12 mm |

| Compressed air consumption | 1.1 m³/h (20 L/min) | 1.1 m³/h (20 L/min) |

| Compressed air pressure | 0.5–0.7 MPa | 0.5–0.7 MPa |

| Cooling water consumption | 0.19 m³/h (3.2 L/min) | 0.19 m³/h (3.2 L/min) |

Note: DPH190D is suitable for R&D and small batch production, while DPH220D is suitable for small to medium batch production. Models can be selected according to required output, product size, and material specifications.

-

- Rotary feeding station

-

- Universal feeding station, Alu-Alu (irregular shaped) feeding station

-

- Heat sealing station

-

- Punching station

A new triple-servo machine was added to the production line to meet capacity requirements. The DPH220D integrated with the existing line, significantly improving production efficiency.

For small batch R&D production, the DPH190D allowed rapid parameter adjustment via HMI, reducing mold change time and supporting multiple product types.

Yes. Different pharmaceuticals and packaging materials (PVC, PVDC, PP, PE, aluminum foil, cold-stamped aluminum, etc.) have specific requirements for equipment compatibility, heat sealing, and operation stability. Customization according to packaging material is part of standard machine design and manufacturing procedures.

Alu-PVC and Alu-Alu formats can be quickly interchanged, reducing line or machine change requirements and ensuring continuous multi-product contract manufacturing.