Fiber Laser Cutting System

Fiber lasers output high laser energy density laser beam that focuses on the surface of the workpiece, so that the irradiated area is instantly melting and gasified. Advantages of optical fiber laser cutting machine are high beam quality, stable beam, and low heat output, with no thermal damage to the workpiece, suitable for cutting difficult metal materials, such as copper and zinc, cutting ultra-thin materials and small and complex geometric parts.

Configuration of Fiber Laser Cutting System

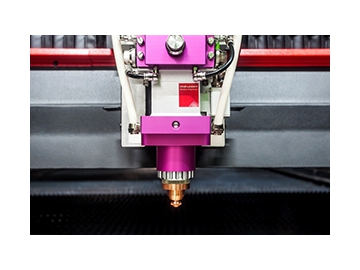

Laser cutting head

The laser cutting head which is designed by Swiss Bystronic, adopts the unique optical technology and the unique structure design, so that the laser beam has higher quality, better focusing ability and more stable cutting performance.

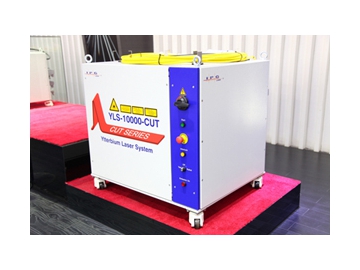

Laser sources

Laser Source is equipped with special cooling device to keep the indoor and the outdoor temperature always consistent, so that the fiber laser can work in a stable environment for a long time to extend the service life of laser cutting equipment.

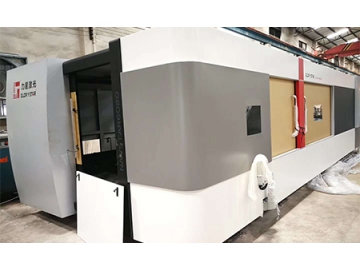

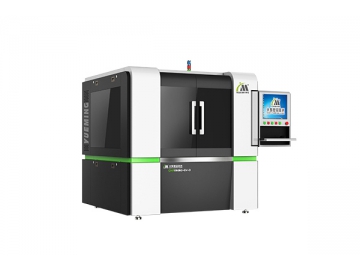

The cutting machine structure is designed by Swiss Bystronic

The body structure of the new generation D-FAST cutting machine is designed by Swiss Bystronic and debugged by the professional technical team from Bystronic headquarter. The laser equipment has characteristics of higher stability, better cutting quality and faster cutting speed.

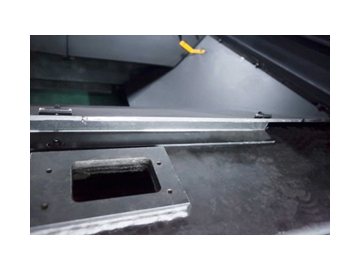

Light barrier design

For the safety of operators, we added a thickened metal light barrier plate in laser cutting machine. For the cutting equipment of 750w-1500w, we use the metal light barrier plate with a thickness of 6mm, while for the cutting equipment of 2000-4000w and 6000-10000w, 8mm metal light barrier plate and 10mm metal light barrier plate are respectively used.

Bilateral sliding door

For the laser cutting machine with protective cover, we take the lead in adopting the design of bilateral sliding door, which not only effectively saves space, but also makes the daily work of equipment maintenance, inspection and maintenance more convenient.

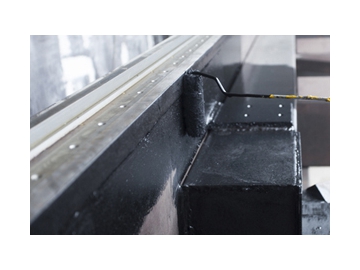

Manual brush-coating

The coating of machine tool body surface is hand-brushed. With the force formed when numerical control electric furnace anneals, the coating surface is rapidly shrinking and tightening, thus efficiently improving the coating adhesive force on the surface.

Since the machine tool is generally placed directly on the floor of the workshop, the ordinary coating can be easily peeled off due to moisture, so that causing rust, while the manual brush-coating method can make the machine body has longer service life of 20 years at least.

Quality is derived from technology, and also from the production process. The goal of machine tool coating is not just beautiful appearance, the most important is to achieve the purpose of moisture resistance and rust prevention, to create greater value for users.

Stress-relief treatment

There are two large high temperature numerical control electric furnaces used for the stress-relief treatment of the machine tool, to ensure the accuracy of the machine tool is stable for a long time

Control system

Combined with the technology of Swiss Bystronic and our own strong optical development capabilities, we develop and design an intelligent touch screen control system so that the operation interface is more simple, convenient and flexible.

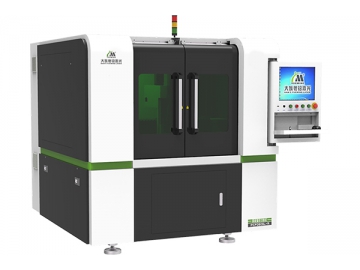

600×600mm High Precision Camera Positioning Fiber Laser Cutter, CMA0606D-GV-B Laser Cutting System

lasercut-group.com

600×600mm High Precision Camera Positioning Fiber Laser Cutter, CMA0606D-GV-B Laser Cutting System

lasercut-group.com

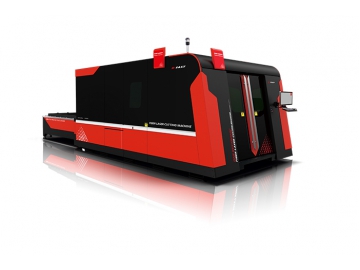

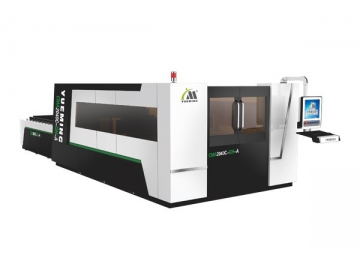

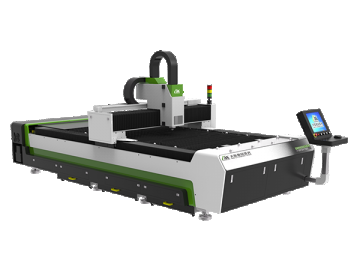

3000×1500mm Fiber Laser Cutter with Gantry Rack Double Drive System, CMA1530C-G-E

lasercut-group.com

3000×1500mm Fiber Laser Cutter with Gantry Rack Double Drive System, CMA1530C-G-E

lasercut-group.com

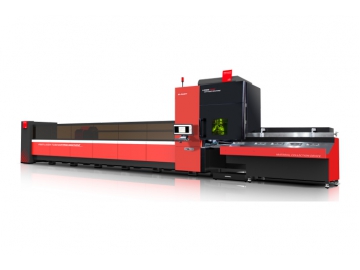

3000×1500mm Plate and Tube Fiber Laser Cutter, CMA 1530C-G-C Laser Cutting System

lasercut-group.com

3000×1500mm Plate and Tube Fiber Laser Cutter, CMA 1530C-G-C Laser Cutting System

lasercut-group.com