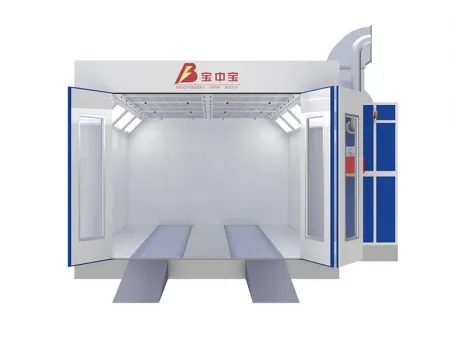

CLASSIC Series Automotive Paint Booth

The CLASSIC series automotive paint booth is a flagship product of our company, known for its stable and reliable performance. Trusted by many customers, this series has earned its reputation through consistent quality and functionality. The CLASSIC paint booth series is not just another paint booth; it has been carefully optimized, balancing efficiency and environmental sustainability essential for achieving high-quality automotive finishes, making it one of the most sought-after models on the market.

Designed to meet high production demands, this spray booth is easy to maintain and operate, making it an ideal solution for auto shops that prioritize both performance and efficiency. Whether you are running a high-volume operation or focusing on specialized, precision work, the CLASSIC series automotive paint booth offers the reliability and performance you need to succeed.

- Length: 6.900

- Width: 4.000

- Height: 3400 mm (outside), 2650 mm (inside)

-

Low Noise

Our spray booths operate with low acoustic emissions, averaging 73 dB, ensuring a quieter working environment. -

Double Turbine

Dual turbines minimize vibrations during startup and operation, ensuring consistent airflow and reducing turbulence. -

Double Glazing

The double glazing with an air chamber helps to prevent heat loss, ensuring stable temperature control. -

Laminated Glass

Laminated glass is used throughout the spray booth for enhanced safety and durability. -

High Modularity

Flexible design allows for easy installation in various space configurations, tailored to meet specific customer requirements. -

Spare Parts

We provide authentic spare parts to maintain optimal performance throughout the equipment's lifespan.

-

LED Lights

Our spray booths feature LED lighting with over 1000 lux for excellent visibility. -

Digital HMI Touchpad (Optional)

Standard installation includes an HMI digital control panel with intuitive pre-programmed settings. -

Insulated Roof (Optional)

The insulated roof plenum is designed to reduce heat loss, improving energy efficiency. -

Top Brands Components

The entire frame is constructed using components from leading European brands. -

Compliance with European Standards

Our products are fully manufactured in accordance with CE standards. -

Specialized Technical Service

We offer comprehensive technical and after-sales support to ensure continued satisfaction and performance.

Door

| 3-wings frontal door | W3000×H2600 mm |

| Shutters supplied with inspection windows and safety glasses | W550×H1800 mm |

| Personnel door | W800×H2000 mm |

Air Generator Unit

| Average air speed into the empty cabin | 0.25 m/s |

| Cabin’s internal noise level | < 75 dB, 73 dB average |

| Thermal power | 180,000 Kcal/h (200 kW) |

Thermal Equipment

| Type | Riello G20 |

| Burner consumption | Diesel (gasoil) |

| Recycling | Yes |

| Max. temp. in drying phase | 80° |

Air Extractor Unit

| Air flow | 24,000 m³/h |

| Motor power | 7.5 kW |

| Noise level inside the cabin | < 75 dB, 73 dB average |

Lighting

| Type | CE Standards – inspection from inside |

| No. of tubes/Lux | Upper lights: 8 fixtures×4 pcs = 32 pcs Led lighting; Side lights: 8 fixtures×2 pcs = 16 pcs Led lighting Intensity 950Lux |

Floor

| Type | Metal Basement |

| Dimensions | 6.900×4000×H300 mm. |

| Loads (punctual/distributed) | 650 kg per wheel print |

| Filters (type) | Paint-Stop / EU3 |

Control Panel

| Type | The button type control panel is equipped with multi-protection for the main circuit. It features light switches, spraying modes, temperature rise settings, baking controls, time setting, failure indicators, temperature limit controller, emergency stop, and breakdown alarm |

Isolation

| Fontal Door | Improved construction with no loss |

| Roof | Not isolated plenum |

| Panels | With EPS thermal and acoustic insulation |

Power Requirements

| Power | 16-16.5 kW approx. |

| Tension | 400V-50Hz (3PH N PE) |

3-wing Front Door

The front door is constructed with a steel-tube load bearing chassis, providing support for the large central door. It includes the following features:

- Each of the door wings is equipped with perimeter gaskets made from high neoprene rubber, ensuring a tight and secure seal.

- All the shutters include inspection windows equipped with safety glass, offering clear visibility and enhanced protection.

- The door’s locking system is built with durable steel components with reinforced handle for added security.

- The door is thermally insulated with EPS (Expanded Polystyrene) to enhance energy efficiency and maintain stable temperatures within the spray booth.

Service Door

Service door is strategically located at side of the cabin for easy access. It includes the following features:

- Equipped with a safety lock with overpressure protection, ensuring safe operation

- Fitted with a porthole with safety glass, providing clear visibility for inspection without compromising safety

- The door is thermally insulated with EPS (Expanded Polystyrene) to enhance energy efficiency and maintain stable temperatures within the spray booth.

- Designed with an anti-explosion handle to maximize safety in high-risk environments

Side Walls

The side walls are constructed from 50 mm thick sandwich panels, custom-built by BZB. These panels are assembled using a precise male-female interlocking system, eliminating the need for welds or screws, and feature internal EPS insulation with a density of 50 Kg/m³, providing complete perimeter sealing. It includes the following features:

- The panels are engineered to withstand corrosive environments, ensuring long-lasting durability

- Designed to resist solvents effectively, maintaining structural integrity even in challenging conditions

- The smooth surface of the panels allows for effortless cleaning and maintenance, ensuring a hygienic and pristine environment.

Filtering Ceiling

The filtering ceiling is built with a sturdy structure of plane trusses and section bars, holding filtering panels in white frames secured with Bakelite pommels. Made from painted galvanized sheet metal, it ensures a perfect hermetic seal.

- Constructed from painted galvanized sheet metal, ensuring a secure hermetic seal

This system achieves a filtration efficiency of 99.8%, compliant with AFI standards. The filters are heat-resistant up to 120°C, self-extinguishing according to DIN 53438 - Class F1 standards, and saturated with fixing resin dust for enhanced durability.

- Filtration efficiency of 99.8%, heat-resistant up to 120°C.

- Self-extinguishing filters saturated with resin dust for added durability.

Lighting

Top lighting is installed in an inclined position on both sides of the cabin ceiling.

- Easily removable from inside the cabin

- Constructed with hermetically sealed LED tubes, protected by laminated glass, metal frames, and neoprene gaskets

- Certified to meet CE standards

- Delivers high-performance neutral light

- Estimated light intensity of 800 lux

Metal Basement with Ramps

The metal basement, standing at 300mm in height, features modular panels of electro galvanized grades, designed with two lines grill and three lines checkered plate lines, one-piece design enables the platform to withstand heavy workpieces with maximum weight to be supported of 650 Kg for wheel print. Besides, there are several under-grates metallic looms in order to close central zones where suction is not provided, with paint-stop filter.

- Easy handling and cleaning.

Ventilation Unit - Inlet

The booth is supplied with a single power unit located on the side of the cabin, equipped with pre filtering cells. The power unit has a surface structure made from panels with two sheets of galvanized iron filled with rock wool insulation. This ventilation structure includes:

- Two motors of 4 kW

- Two high efficiency turbine fans, for a total airflow of 24,000 m³/h

- One stainless steel heat exchanger made of stainless steel (SUS304), δ=1.2 mm, utilizes double-layer stainless steel tubes delivering a heat exchange capacity of 180,000 Kcal/h (200 kW)

- With gasoil (diesel) burner

The power unit is equipped with:

- Safety and control thermostat

- Pre-filtering cells inserted on special slides and frames.

- The power unit is supplied with connecting ducts between the power unit and the plenum.

Ventilation Unit - Air Extraction

Extractor unit

Centrifugal fan and filtering equipment consisting of two layers of dry filters located under the fans.

- One 7.5 kW motor

- One high-efficiency turbine fan, for an airflow of 20,000 m³/h

- Holding structure in press bent galvanized iron

- Closure panels insulated

- One manual calibration damper

Documentation provided with the booth:

- User manual, program management guide, system description and detailed usage instructions

- Electrical diagrams of the system

Control Panel

Designed to meet CE standards of control system, it includes the following components:

- Ventilation control with start/stop functions, adjustable based on the work phase

- Temperature programming for precise control, including start/stop settings

- On/off control for the booth’s lighting

- Fault alarms to notify any system issue

- Ventilation failure detection

- Power failure alerts

- Temperature monitoring inside the cabin

- Service hours counter to track usage

- Emergency stop for immediate shutdown in case if emergency

Documentation provided with the booth:

- User manual, program management guide, system description and detailed usage instructions

- Electrical diagrams of the system

- Paint Booth BZB-C701

- Air Generator Unit

Airflow: 24,000 m³/h

Motor Power: 2×4 kW - Air Extractor Unit Airflow: 24,000 m³/h

- Power Requirements: 16.5 kW approx.

- Air Generator Unit

- Paint Booth BZB-C702

- Air Generator Unit

Airflow: 30,000 m³/h

Motor Power: 9 kW - Air Extractor Unit Airflow: 26,000 m³/h

- Power Requirements: 16 kW approx.

- Air Generator Unit

- Paint Booth BZB-C703

- Air Generator Unit

Airflow: 24,000 m³/h

Motor Power: 2×4 kW - Air Extractor Unit Airflow: 24,000 m³/h

- Power Requirements: 16.5 kW approx.

- Air Generator Unit