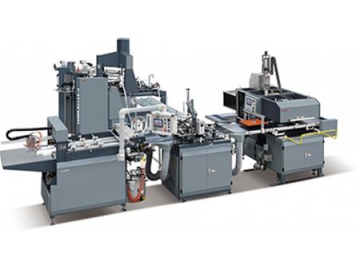

S460/460C Automatic Rigid Box Making Machine

Rigid box machinery, rigid box manufacturing line

- The feeder in this machine adopts back-push feeding system, which is controlled pneumatically, and its structure is simple and reasonable.

- The width between stacker and feeding table is adjusted concentrically in the center. The operation is very easy without tolerance.

- Adopt imported ultrasonic double paper tester, featuring in simple operation, which can keep two pieces paper from entering into the machine at the same time.

- Automatic circulation, mixing and gluing system for hot-melting glue. (Optional device: glue viscosity meter).

- Hot-melting paper tape automatic conveying, cutting, and finish pasting the inner box quad stayer (four angles) of cardboard in one process.

- The vacuum suction fan under the conveyer belt can keep the paper from deviating.

- The paper and cardboard inner box employs hydraulic rectifying device to spot correctly.

- The wrapper can continually wrap, fold ears and paper sides and form in one process.

- The whole machine employs PLC, photoelectric tracking system and HMI to automatically forming boxes in one process.

- It can automatically diagnose the troubles and alarm accordingly.

| Parameters | S 460C Box maker | S 460 Box maker | |

| Sheet size (A×B) | A min. A max. B min. B max. | 95mm 610mm 180mm 850mm | 95mm 610mm 180mm 850mm |

| Cardboard size (C×D ) | C D | 600mm 800mm | 600mm 800mm |

| Sheet thickness | 100-200gsm | 100-200gsm | |

| Cardboard thickness | 0.8-3mm | 0.8-3mm | |

| Finished box size(W ×L×H ) | Min. Max. | 100×50×15mm 420×320×120mm | 100×50×15mm 420×320×120mm |

| Edge folding depth | R min. R max. | 10mm 100mm | 10mm 30mm |

| Fold ear depth | R min. R max. | 10mm 125mm | 10mm 125mm |

| Positioning accuracy | ± 0.3mm | ± 0.3mm | |

| Production speed | ≤20 sheets/min | ≤25 sheets/min | |

| Sheet stacking height | 300mm | 300mm | |

| Cardboard stacking height | 1000mm | 1000mm | |

| Electrical power | 10kw/380V/3phases | 10kw /380V/3phases | |

| Air supply | 10L/min 0.6Mpa | 10L/min 0.6Mpa | |

| Machine weight | 4500kg | 4500kg | |

| Machine dimension | L6800×W 4100×H 2800mm | L6800×W 4100×H 2800mm |

Remark

1. The max and mini sizes of the boxes are subjected to those of the paper and the quality of the paper.

2. The production capacity is 20 boxes per minute. But the speed of the machine depends on the sizes of the boxes.

3. We don’t provide air compressor.

Conditions for configuration

1. space: 14mx10m About 140m2

2. manning: master-1 person operator-3 person

1.Automatic case making machine

2.Automatic lining machine

3.Automatic turnover machine

4.Automatic adhesive machine

5.Automatic wall board making machine

Conditions for configuration

1. space: 17mx12m About 200m2

2. manning: master-1 person operator-4 person

1.Automatic case making machine

2.Conveyor

3.Automatic lining machine

4.Hardcover turnover machine

5.Automatic adhesive machine

6.Automatic rigid box making machine

7.Feeding and Collecting part

8.Automatic packing machine