Toothed Roll Crusher

Turnkey Project Solutions

Complete Equipment & Engineered Systems

The double roll crusher is used for crushing sandstone, shale, frozen soil, clay, carbide slag and other similar materials with a low compression strength that is less than 40MPa. Compared to other types of crushing equipment, the double roll crusher features a simpler working process and easy maintenance, making it more suitable for the crushing of viscous materials and similar materials.

| Model | Maximum feed size(mm) | Discharge size(mm)(sieve residue 20%) | Material's moisture content(%) | Material's plasticity index | Productive capacity (t/h) |

| ≤300 | ≤50 | ≤25 | 15-22 | 60-90 | |

| ≤300 | ≤50 | ≤25 | 15-22 | 100-120 | |

| ≤300 | ≤50 | ≤25 | 15-22 | 150-200 | |

| ≤500 | ≤50 | ≤25 | 15-22 | 250-300 | |

| ≤500 | ≤50 | ≤25 | 15-22 | 350-400 | |

| ≤600 | ≤50 | ≤25 | 15-22 | 450-500 |

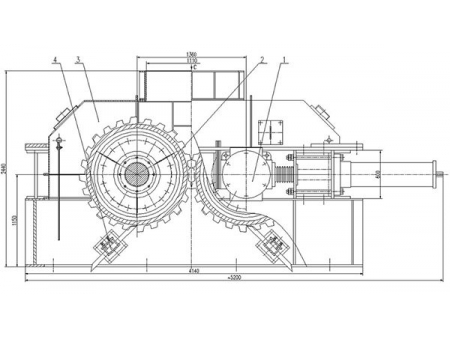

The double roll crusher is comprised of the crushing rolls, machine shell, scraper device with drive, grease lubrication system, gas-liquid compression system and V-belt tensioner.

- Movable roll

- Fixed roll

- Machine shell

- Scraper

Crushing roll

Roll tooth

The crushing roll is made of an abrasion resistant and corrosion-resistant high manganese steel. The roll teeth are laid in a staggered arrangement, making the crushing process more efficient.

Scraper device

The mud scraping device is made of wear-resistant materials, and is used to prevent materials from sticking to the rolls, thus ensuring an effective tooth height and suitable gap for materials to pass through. This also ensures the proper breaking and pressing strength.

Hydraulic system

The hydraulic system is used for adjusting the crushing roll tooth gap in order to meet the different requirements for particle size discharging.

Lubrication system

Using a lithium base grease, the lubrication system is powered using a specialized motor, so that the oil feeding speed from the pipe line to each lubricating point is regulated. The four spindles can not only be lubricated individually, but also simultaneously, thus ensuring they are easy to maintain.

V-belt tensioner

When any material that can’t be crushed enters the chamber, the movable roll will quickly move backwards and the V belt will be loosened. The belt will not slip or become twisted due to the elastomer action in the tensioning device. The elastomer is produced by ROSTA, and features a stable performance and long service life.

- Under the joint action of pressure and shear force, the material is jammed and crushed between two opposite rotating rolls, then is discharged from the gap between the roll teeth. If any material sticks to the roll surface, it is removed using the scraper.

- The machine frame design allows the moving roll bearing seat to move horizontally along the slide. If there is an object that cannot be crushed in the roller, the roll will move backward and discharge the foreign material in order to protect the equipment against damage.

- The flexible resin curtain prevents viscous material with water content from sticking to the inner surface of the crushing chamber.